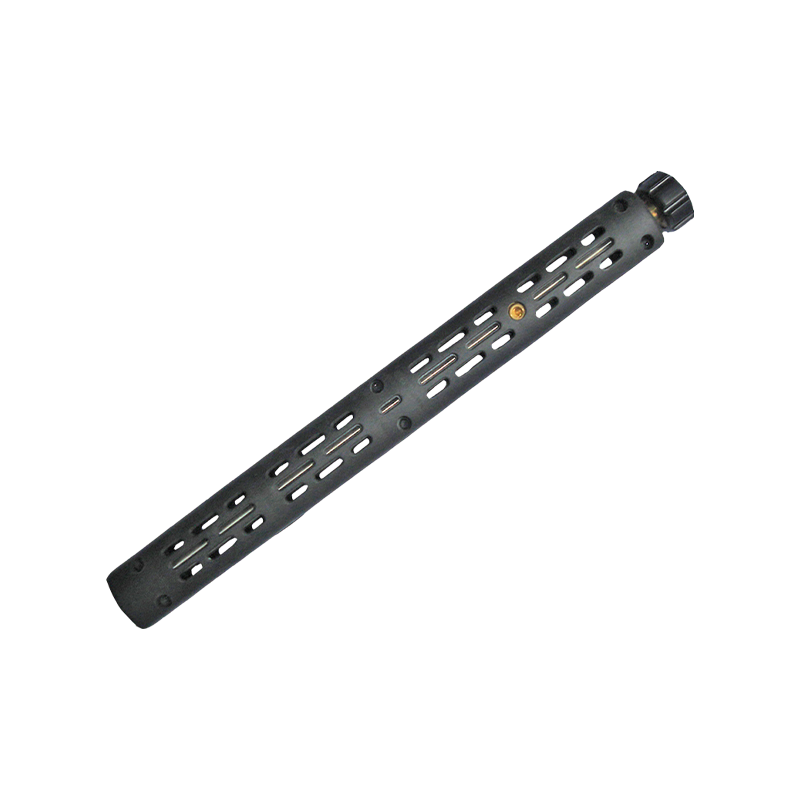

The core of the design of the trigger gun ventilation grip rear section is efficient heat dissipation. This rear section is mainly used in the gun barrel part of the high-temperature hot water cleaning machine. Since the working water temperature of the cleaning machine is as high as 100 degrees Celsius, if a conventional injection molded handle is used, the user will feel noticeably hot when holding it. For this reason, the ventilated grip adopts a unique hollow structure design, that is, an air layer is formed between the grip and the gun barrel, and the heat insulation properties of the air are used to effectively block heat transfer. At the same time, the hollow structure also enhances air circulation and promotes the rapid dissipation of heat. This dual heat dissipation mechanism significantly reduces the surface temperature of the grip, ensuring that the user will not feel hot even if operating for a long time, thereby improving the comfort and safety of use. The material of the ventilated grip is selected from high-performance engineering plastics, which has high temperature resistance and wear resistance. It can maintain stable physical properties in high temperature environments, further ensuring the durability and reliability of the product.

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. was established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Trigger Gun Ventilation Grip Rear Section Suppliers and Trigger Gun Ventilation Grip Rear Section Factory, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

NEWS

-

What lubrication or assembly considerations are necessary to maintain smooth operation of the Ball Quick Coupling?

Importance of Proper Lubrication — Lubrication is a critical factor in ensuring the smooth engagement, disengagement, and overall reliability of a Ball Quick Coupling. The internal mechanism, includ...

READ MORE -

What design features of the Weep Trigger Spray Gun prevent clogging or buildup during use with thick or particulate-laden liquids?

Wide-Bore Fluid Channels: The Weep Trigger Spray Gun incorporates fluid channels that are significantly wider than those found in standard spray guns, specifically designed to handle high-viscosity ...

READ MORE -

How does the Weep Trigger Spray Gun maintain spray consistency when used in high-pressure or high-volume industrial environments?

Precision Internal Valve and Fluid Control Mechanisms: The Weep Trigger Spray Gun utilizes a high-precision internal valve system engineered to regulate fluid flow accurately regardless of variation...

READ MORE -

How does a Pressure Washer Filter protect the pump and nozzle from debris and particulate contamination during operation?

Primary Barrier Against ContaminantsA Pressure Washer Filter functions as the first line of defense in the water intake system, intercepting particles and contaminants before they can enter critical...

READ MORE

English

English русский

русский

0086-13003738672

0086-13003738672