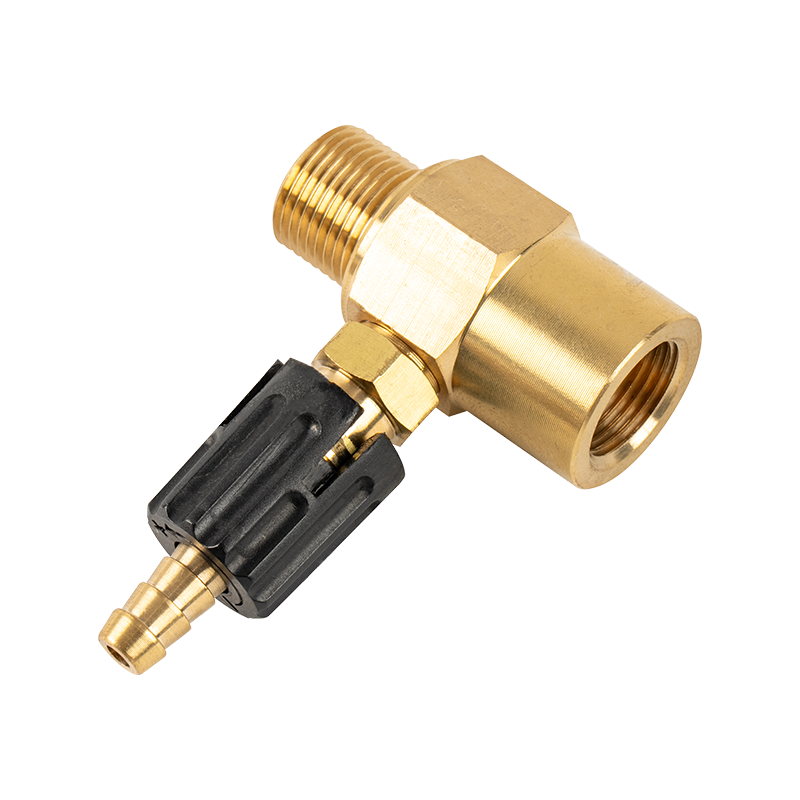

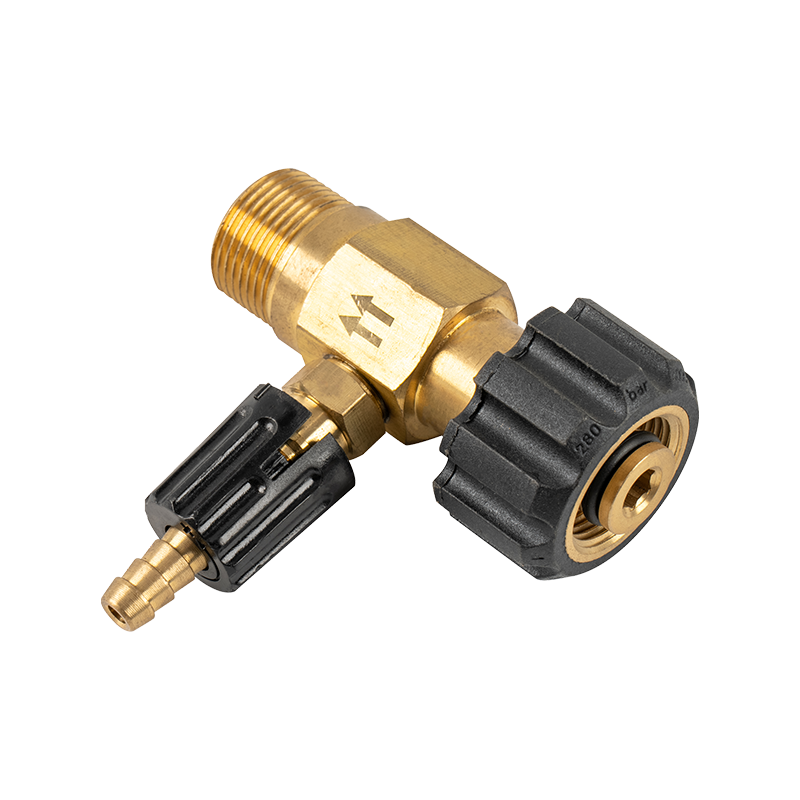

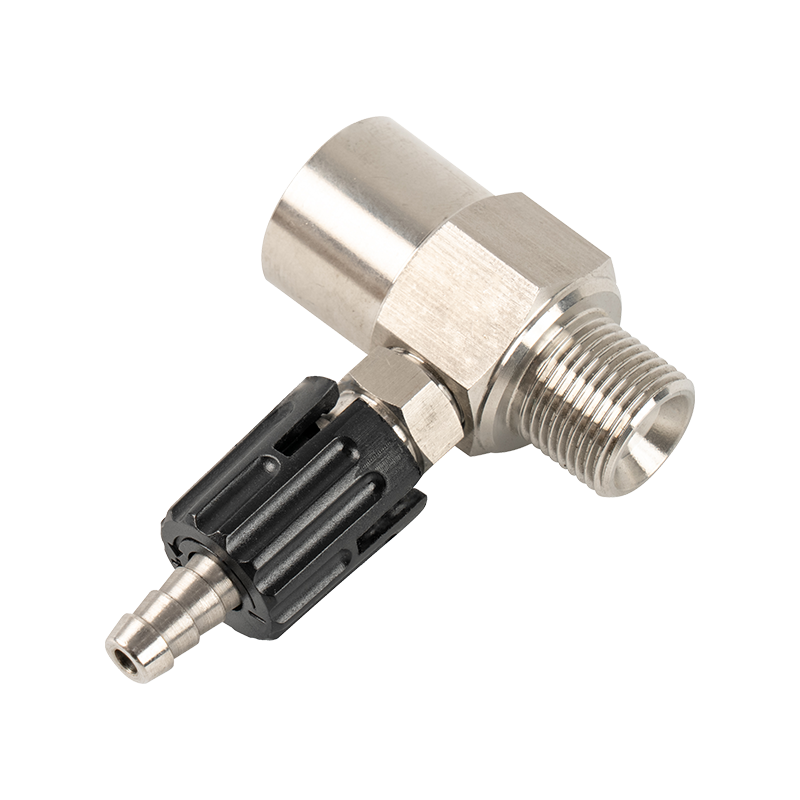

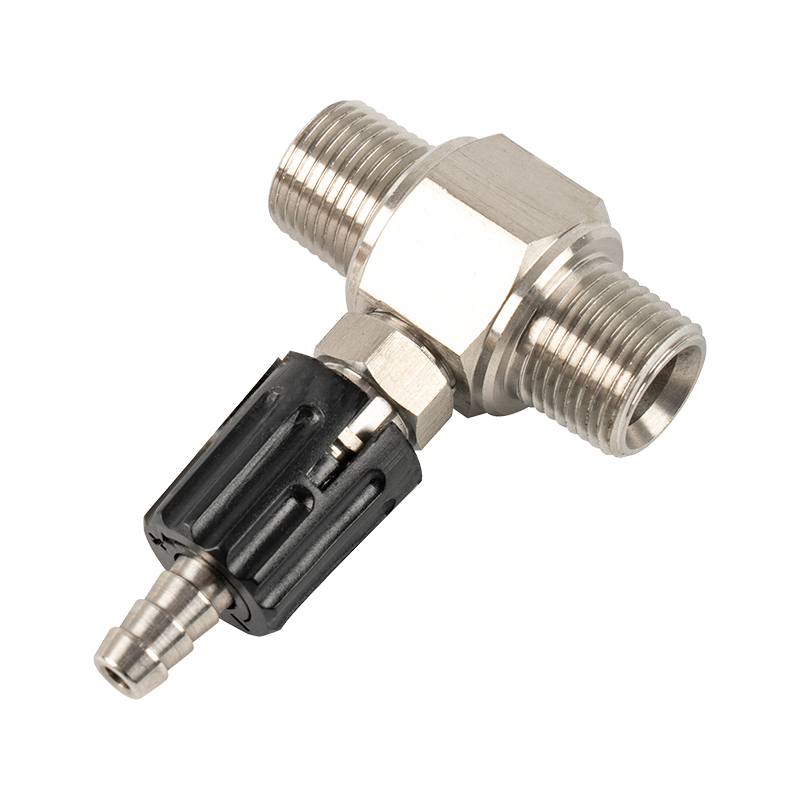

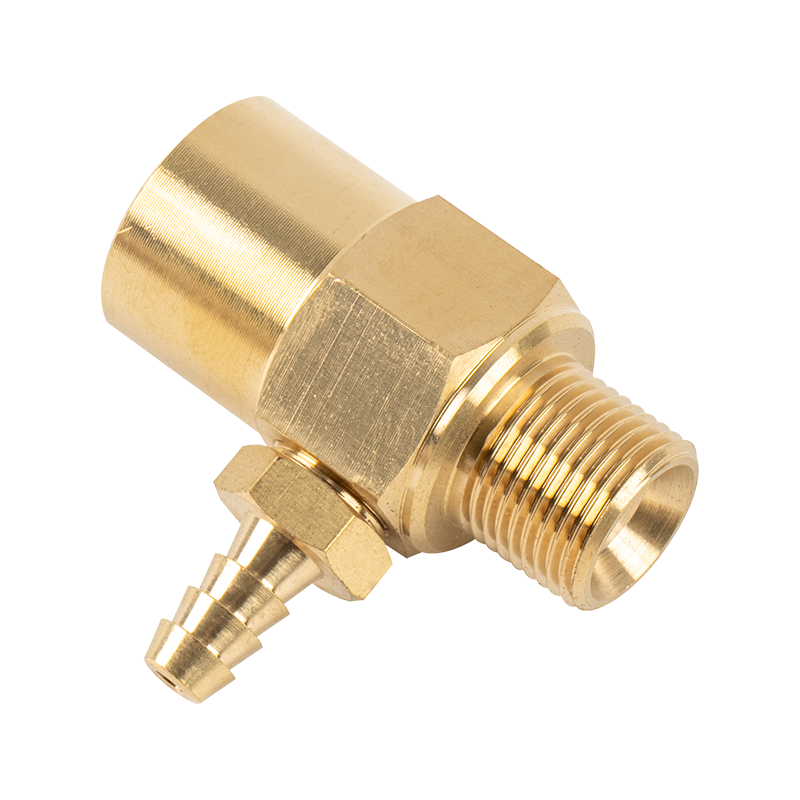

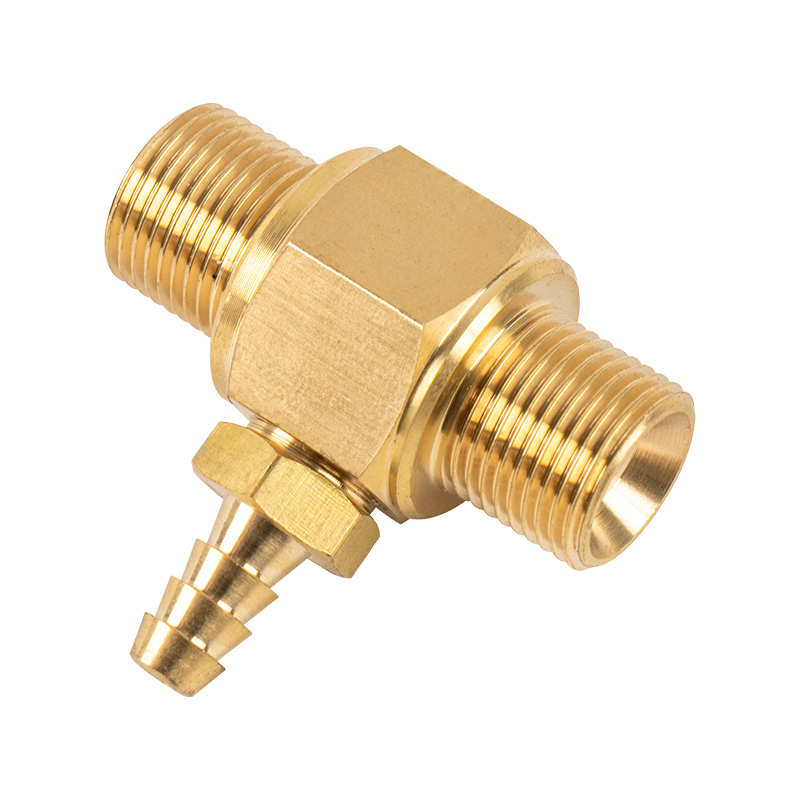

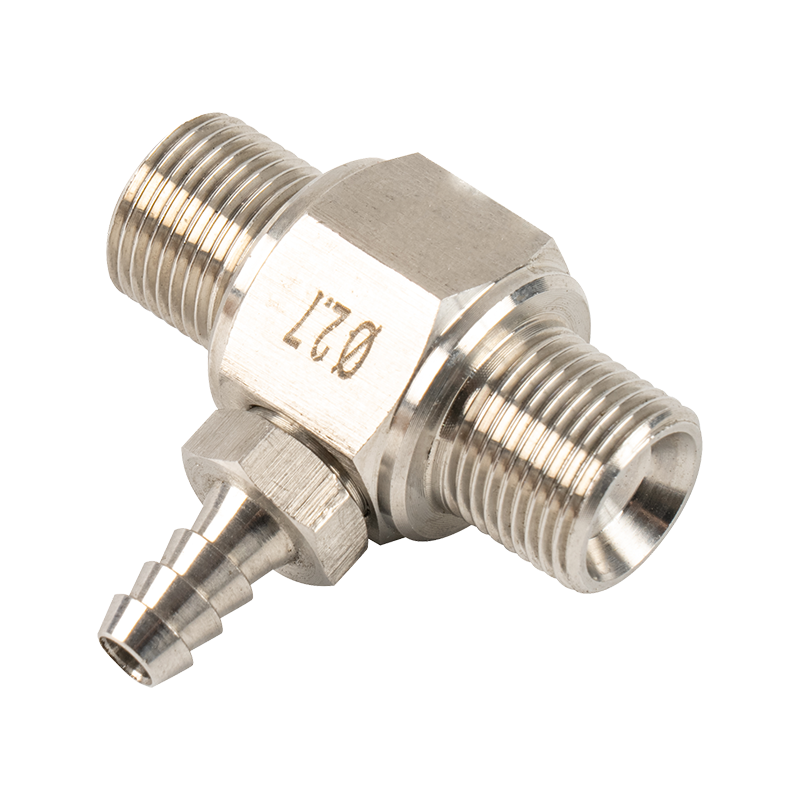

The adjustable chemical syringe is a very commonly used accessory in high-pressure cleaning machines...

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Stainless Steel Chemical Injectors Manufacturers and Adjustable Chemical Injectors Suppliers, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

NEWS

-

What lubrication or assembly considerations are necessary to maintain smooth operation of the Ball Quick Coupling?

Importance of Proper Lubrication — Lubrication is a critical factor in ensuring the smooth engagement, disengagement, and overall reliability of a Ball Quick Coupling. The internal mechanism, including the ball lock system, sleeve, seals, and spring components, operates under high stress and frequ...

READ MORE -

What design features of the Weep Trigger Spray Gun prevent clogging or buildup during use with thick or particulate-laden liquids?

Wide-Bore Fluid Channels: The Weep Trigger Spray Gun incorporates fluid channels that are significantly wider than those found in standard spray guns, specifically designed to handle high-viscosity fluids and liquids containing particulate matter. The increased internal diameter reduces resistance...

READ MORE -

How does the Weep Trigger Spray Gun maintain spray consistency when used in high-pressure or high-volume industrial environments?

Precision Internal Valve and Fluid Control Mechanisms: The Weep Trigger Spray Gun utilizes a high-precision internal valve system engineered to regulate fluid flow accurately regardless of variations in input pressure. In high-volume or industrial environments, fluid supply pressure can fluctuate ...

READ MORE

Message Feedback

Industry Knowledge Extension

As an important accessory in high-pressure cleaning machines, the core function of the chemical injector is to effectively mix detergents, disinfectants or other chemical liquids with high-pressure water flow to improve the cleaning effect. Specifically, the chemical injector uses the power of high-pressure water flow to suck the chemical liquid into the injector and spray this mixed solution onto the surface to be cleaned through a specific nozzle and pipe. Since the chemical injector can adjust the flow and concentration of the chemical, it can optimize the cleaning process according to different cleaning needs.

The working principle of the chemical injector usually includes two key parts: the injection valve and the suction pipe. When the water flows through the injection valve, the negative pressure in the syringe causes the chemical cleaner to be sucked in through the suction pipe and mixed with the water flow. In this process, the high pressure of the water flow and the cleaning ability of the chemical combine to form a strong cleaning solution. By adjusting the settings of the injector, the injection ratio of the detergent can be precisely controlled to deal with different types of dirt.

The advantage of this technology is that it can greatly improve the cleaning efficiency and disinfection effect. In many fields such as industrial cleaning, food processing, and car cleaning, the role of detergents cannot be underestimated. Many stubborn oils, industrial residues, grease, stains and microorganisms can be easily removed by this efficient mixing method. Especially in terms of disinfection, chemical injectors combined with disinfectants can effectively remove pathogenic microorganisms such as bacteria and viruses, meeting the hygiene requirements of different places.

Chemical injector has been widely used in many industries, especially in those fields with high requirements for cleaning, disinfection and handling of stubborn dirt.

Industrial cleaning: The application of chemical injector in the industrial field is crucial, especially in manufacturing, automobile maintenance and large equipment cleaning. Many industrial equipment are often troubled by stubborn dirt such as oil, paint, rust, etc., which are often difficult to remove by traditional cleaning methods. In this case, chemical injector can combine powerful industrial detergents with high-pressure water flow to quickly decompose dirt and thoroughly clean. Especially in heavy industrial fields such as chemical, machinery, and shipbuilding, chemical injector has become an indispensable equipment with its efficient cleaning effect.

Car washing: Car washing is also an important application area for chemical injectors. In car repair shops and car wash centers, chemical injectors are often combined with car wash liquids or special detergents to remove stubborn stains such as oil, shellac, and bird droppings on the car body. Chemical injectors can not only clean the exterior body through the combination of high-pressure water flow and detergent, but also effectively clean the engine, tires, and hard-to-reach places such as the bottom of the car. Especially for car detail cleaning, chemical injectors can provide uniform and efficient cleaning effects.

Disinfection of public facilities and equipment: With the improvement of public health awareness, public places such as hospitals, schools, and shopping malls have higher and higher requirements for hygiene. Especially during the epidemic prevention and control period, disinfection work has become particularly important. Chemical injectors combined with disinfectants can achieve large-scale and efficient disinfection, completely kill bacteria, viruses and other pathogenic microorganisms, and effectively prevent cross-infection. In the regular disinfection of public facilities, the precise injection function of chemical injectors ensures the rational use of disinfectants, which not only improves the disinfection efficiency, but also reduces the disinfection cost.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. As a manufacturing company with 14 years of industry experience, Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. has accumulated rich experience in the research and development and production of chemical injectors and high-pressure cleaning equipment. The company always pays attention to product innovation, has an independent R&D center, and is committed to continuously upgrading technology and optimizing products according to market demand. With advanced production equipment, skilled technical workers and perfect production lines, Baige Machinery ensures efficient production and high quality of products.

In order to ensure that the chemical injector always maintains an efficient working state during long-term use, regular maintenance and care are essential. Scientific and reasonable maintenance can not only extend the life of the equipment, but also ensure the consistency of the cleaning effect.

Regular inspection and cleaning: The main components of the chemical injector include injection valves, suction pipes and nozzles, etc. These components are prone to accumulate residual chemicals during long-term use, resulting in blockage or decreased function. To avoid this, all components should be cleaned in time after use, especially nozzles and injection pipes. In addition, the filter of the injector should be checked regularly to ensure that the passage of water and chemicals is unobstructed.

Equipment maintenance: In daily use, chemical injectors require regular maintenance and inspection, especially injection valves and other mechanical parts. Excessive water pressure may cause damage to the equipment, while the corrosiveness of chemicals may damage the equipment materials. Therefore, it is very important to regularly check and maintain the corrosion resistance and mechanical structure of the equipment to ensure that the equipment is not damaged.

Operational safety: Safety is always the top priority when using chemical injectors. Chemical cleaners and disinfectants usually contain strong chemical ingredients that may cause damage to the skin, eyes and respiratory tract. Therefore, during operation, workers should wear appropriate protective equipment, such as rubber gloves, goggles and protective masks. In addition, the chemical label should be carefully read before use and the instructions for use should be followed to avoid dangers caused by misoperation.

Selection and storage of chemicals: Choosing suitable chemical cleaners and disinfectants is essential for the normal operation of chemical injectors. Make sure that the selected chemicals are compatible with the materials of the high-pressure cleaner and injector to avoid reactions between chemicals and equipment. The storage of chemicals should also comply with safety regulations and avoid direct sunlight, high temperature or humid environments to reduce the impact on the quality of the chemicals.

English

English русский

русский

0086-13003738672

0086-13003738672