At the core of an effective lance is its ability to endure continuous high-pressure water flow without distortion, leakage, or performance degradation. This begins with the selection of core materials, which play a pivotal role in the lance’s long-term durability and adaptability to harsh cleaning environments. We uses stainless steel, aluminum alloys, or brass components depending on the expected use case. Stainless steel, for example, is widely known for its excellent resistance to rust, chemicals, and pressure fatigue. It’s especially suitable for environments involving hot water, abrasive particles, or corrosive detergents. Aluminum, though lighter in weight, is often anodized or coated to prevent oxidation and maintain a smooth internal bore, which reduces turbulence during high-pressure water flow. Brass is another material frequently used for its natural resistance to corrosion and excellent machining compatibility. All these materials must be precisely processed to avoid microfractures or weaknesses that can be exposed under repeated pressure cycles. At Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd., located in Ningbo, Zhejiang Province and established in 2011, these material decisions are taken seriously. Their engineers utilize more than 50 advanced pieces of equipment within a 5000-square-meter factory to fabricate Pressure Washer Lances that meet not only ISO 9001:2015 standards but also the specific demands of OEM and ODM clients around the world.

Another vital feature in the design of a high-quality Pressure Washer Lance is its compatibility with various pressure levels and water temperatures. High-end lances must be able to handle pressure ranges exceeding 3000 PSI and in some cases, up to 5000 PSI, especially in industrial applications where cleaning requirements are intensive. This necessitates precise inner bore dimensions to ensure optimal water flow without generating backpressure or turbulent spray patterns. Lances designed for hot water usage or steam cleaning need to have thermal-resistant components and insulation to protect both the user and the internal structure of the lance itself. If the lance lacks the proper thermal shielding or uses inferior sealing materials, the pressure system could suffer from leakage, rapid wear, or even dangerous bursts. To address this, Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. designs its lances with high-temperature resistant seals, anti-scald insulation handles, and pressure-rated connectors that ensure safe operation even in high-temperature environments. Their products are especially well-suited for integration with their foam sprayers, telescopic rods, chemical injectors, and rotary nozzles, providing full system reliability. Their engineering team continually updates designs to handle new combinations of detergents and working conditions by using advanced sealing technology and reinforced tubing. This not only extends the service life of the lance but also enhances user safety and operational confidence in demanding field conditions.

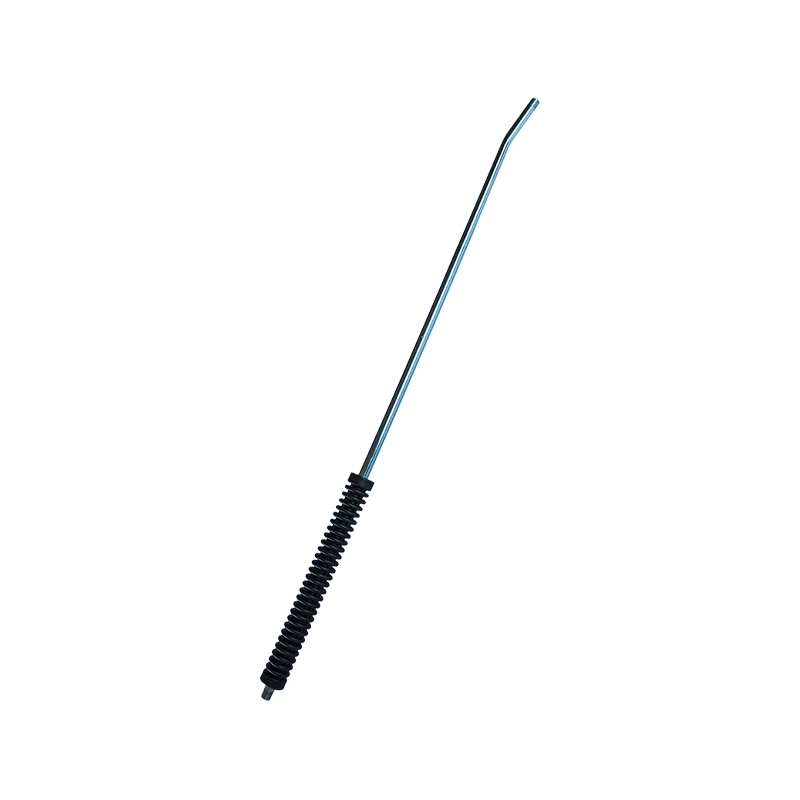

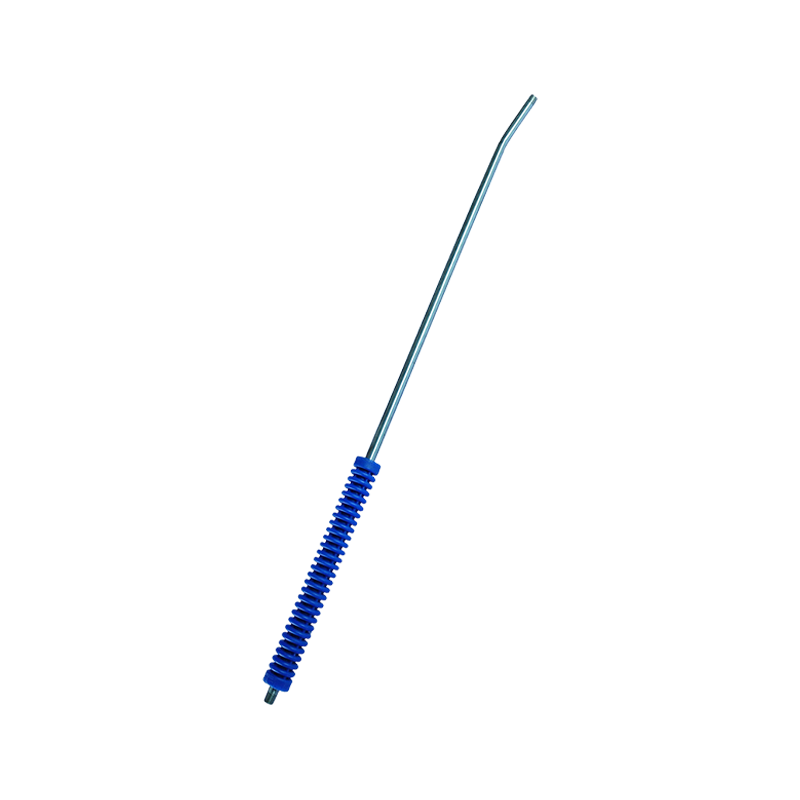

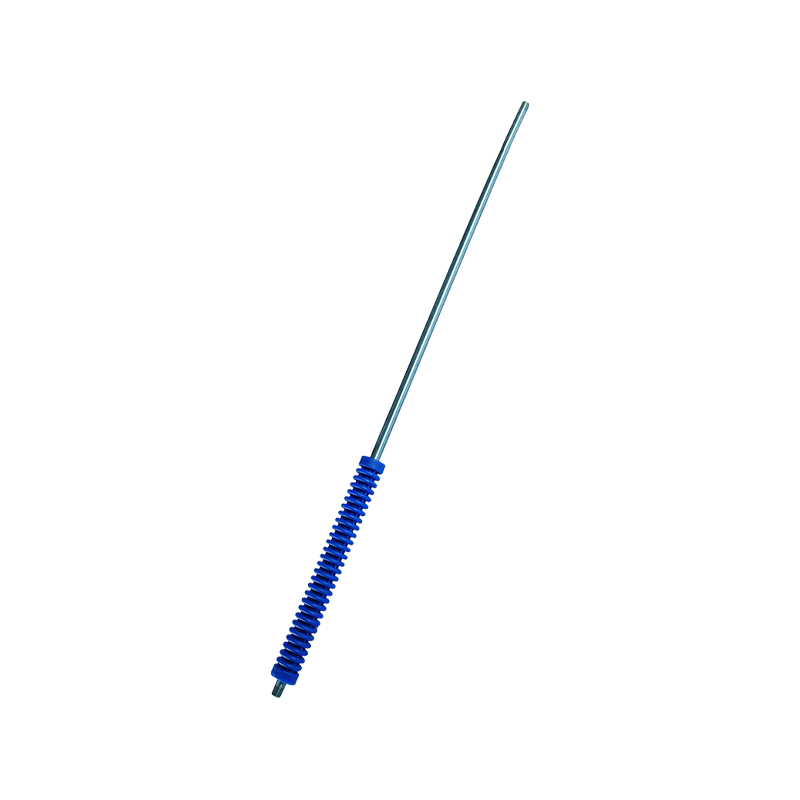

Ergonomic design is another area where a high-performance Pressure Washer Lance must excel. Cleaning operations, particularly in commercial and industrial environments, require extended usage over large surface areas, sometimes at awkward angles or overhead. If the lance is poorly balanced or lacks proper grip design, it can quickly lead to operator fatigue, reduced control, and unsafe handling. High-quality lances are built with user comfort in mind, incorporating features like insulated rubber grips that not only prevent heat transfer but also provide a firm and comfortable hold, even in wet conditions. The curvature of the lance, the angle of the spray outlet, and the location of the trigger or control valve all affect ease of use. Lances that are poorly designed in these aspects tend to produce wrist strain and inaccurate targeting of the spray jet. That’s why Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. ensures that their lances include ergonomic features as a standard part of the design process. With their expertise in producing a wide variety of cleaning machine accessories such as gun barrels, spray guns, and water brooms, they engineer each lance to complement the user's body posture and reduce the physical burden of repetitive cleaning motions. Their custom-designed lances also allow customers to specify dimensions, handle types, and accessory placements based on their specific industry or cleaning application.

The professional Pressure Washer Lance must incorporate versatile connection mechanisms and high interchangeability with other cleaning components. In practice, operators frequently need to change nozzles, adjust spray angles, or switch between detergent delivery and rinsing modes. Without a properly designed connection system, such transitions become time-consuming, prone to leaks, or incompatible with certain fittings. High-performance lances resolve this through the integration of quick-connect couplings, precision-machined threading, and universal mount compatibility. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. manufactures a full suite of connectors, couplings, and quick-release fittings that are designed to integrate seamlessly with their lance products. Whether it's a rotary turbo nozzle, a foam cannon, or a chemical sprayer, all accessories can be attached swiftly and securely. Their in-house quality control ensures that all joints, seals, and mating surfaces are pressure-tested to eliminate risks of leakage or detachment under load. This also means less downtime during cleaning operations, increased equipment uptime, and fewer replacement costs. The company’s OEM and ODM services also allow clients to request specific connection types—metric or imperial threads, male or female couplings, swivel or fixed mounts—which further enhances the lance's versatility in complex operational settings.

Lastly, corrosion resistance and surface protection are crucial to ensuring long-term functionality, especially when the lance is exposed to moisture, UV radiation, and harsh cleaning agents on a daily basis. A lance that rusts internally or externally will eventually fail by clogging, weakening, or seizing up. To avoid this, leading manufacturers apply nickel plating, epoxy coatings, or even polymer-based surface treatments to protect the lance body. Internal surfaces are also treated to prevent pitting and scaling caused by mineral-rich water or chemical additives. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. incorporates advanced anti-corrosion processes into every stage of manufacturing. Their pressure washer lances undergo surface treatment procedures that include polishing, coating, and sealing, which help them withstand harsh environmental conditions. The company’s commitment to long-term quality has made them a trusted supplier not only in China but also internationally. With access to both Ningbo Port and Shanghai Port, they are able to distribute their lances and related accessories globally, ensuring fast delivery and consistent product support. Their quality management system, certified to GB/T 19001-2016/ISO 9001:2015, guarantees that each product meets both national and international performance standards.

English

English русский

русский

0086-13003738672

0086-13003738672