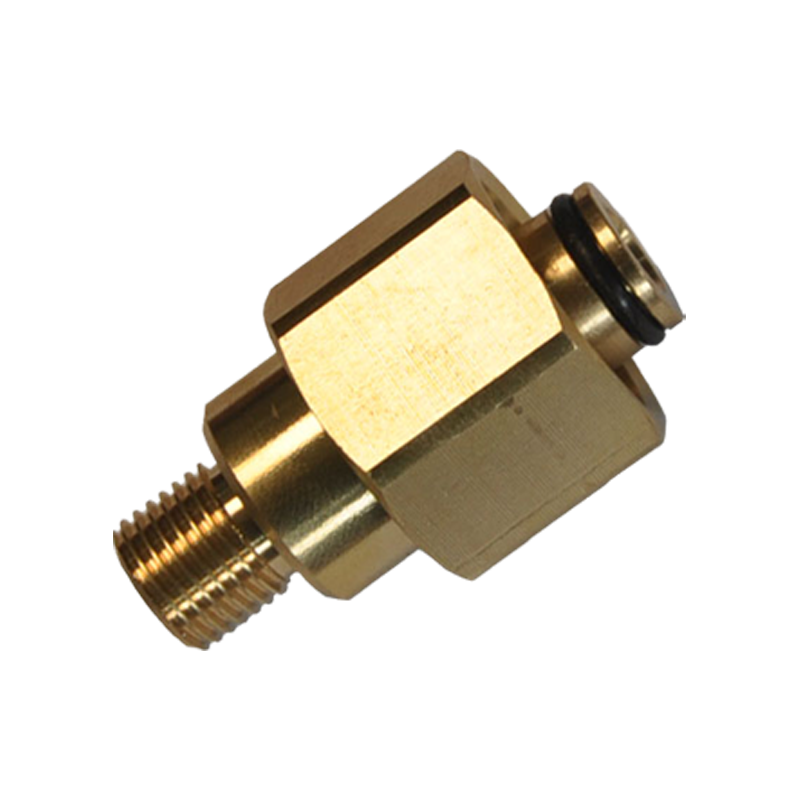

The quick twist lock brass connector is a new type of pipe connection method in the field of cleanin...

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Screw Coupling M22 Manufacturers and Screw Coupling M22 Suppliers, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

Certificate Of Honor

NEWS

-

How does a Pressure Washer Filter protect the pump and nozzle from debris and particulate contamination during operation?

Primary Barrier Against ContaminantsA Pressure Washer Filter functions as the first line of defense in the water intake system, intercepting particles and contaminants before they can enter critical components. Water sources—whether municipal, well, or pond water—often contain microscopic debris s...

READ MORE -

How does the Ball Quick Coupling perform under repeated connection and disconnection cycles, and what is its rated service life?

1. Durability of Structural Components The Ball Quick Coupling is specifically designed for high-cycle operations, where repeated connection and disconnection are routine. Its structural components, including the housing, balls, locking sleeve, and internal retainers, are typically manufactured from...

READ MORE -

How does the Chromed Steel Spray Gun Barrel interact with various nozzle types and air pressure settings to achieve precise coating applications?

Precision Through Barrel-Nozzle Compatibility The Chromed Steel Spray Gun Barrel is a critical component in achieving high-quality, consistent coatings. Its chromed interior surface is highly polished, providing a smooth, low-friction pathway for liquid coatings such as paints, lacquers, primers, or...

READ MORE

Message Feedback

Industry Knowledge Extension

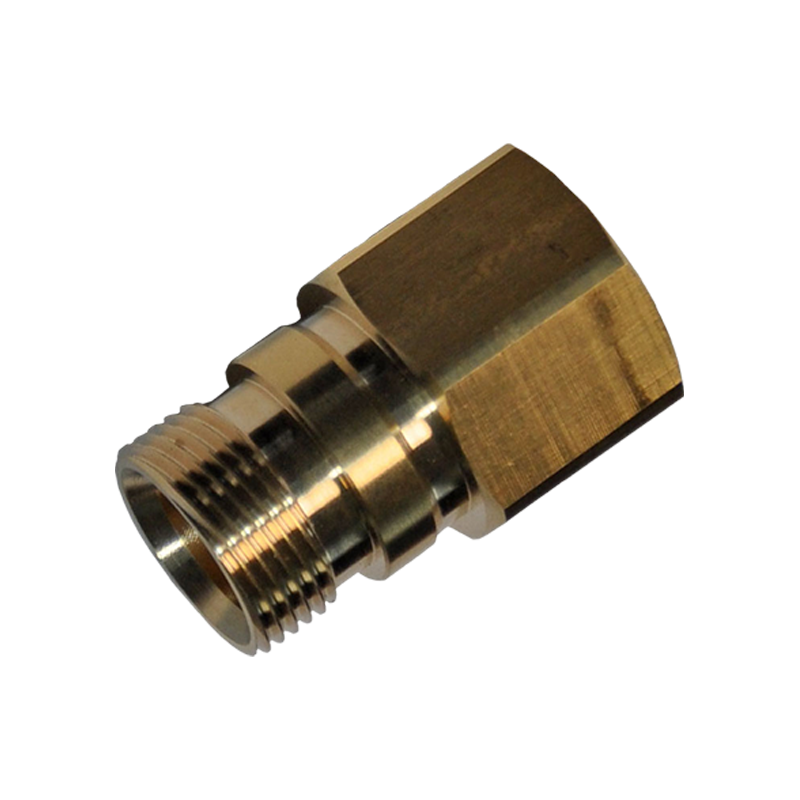

The M22 screw coupling is an engineered solution for achieving secure, leak-proof connections between two components in a wide range of mechanical systems. The design and dimensions of the M22 screw coupling are specifically crafted to ensure maximum compatibility with a variety of fittings, pipes, and other machinery components. As a key manufacturer of M22 couplings, Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. ensures that all of our products are made with precision, meeting both national and international standards for durability and functionality.

The primary feature of the M22 screw coupling is its 22mm nominal diameter, with metric threads that provide a perfect match for connecting components. The threading on the coupling's surface is precisely crafted to ensure a snug fit, which is vital for preventing leakage in high-pressure applications. The thread's design, coupled with the use of materials such as stainless steel, carbon steel, and brass, guarantees that the coupling can withstand harsh environments, whether exposed to moisture, chemicals, or high temperatures.

At Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd., we emphasize the importance of material selection when designing M22 screw couplings. Stainless steel, for example, offers corrosion resistance, while carbon steel provides strength for high-load applications. Brass is often selected for applications requiring good electrical conductivity. Each of these materials contributes to the longevity and robustness of the M22 screw coupling, ensuring it performs reliably in even the most demanding settings.

The M22 screw coupling comes in different configurations, such as straight, elbow, and tee couplings, to cater to a wide array of industrial needs. The flexibility in design options means that businesses can rely on the M22 screw coupling for a variety of applications, from fluid transfer in hydraulic systems to connections in automotive machinery. This adaptability has made M22 couplings a popular choice across industries.

M22 screw couplings provide a range of benefits that make them essential in various industrial applications. At Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd., we prioritize the production of these high-performance couplings, recognizing their value in industries where safety, efficiency, and durability are critical.

Durability and Longevity: M22 couplings are known for their strength and resistance to wear and tear. The materials chosen for manufacturing, such as stainless steel, offer excellent resistance to rust and corrosion, which extends the lifespan of the coupling. This is particularly important for industries like agriculture and manufacturing, where machinery operates in harsh environments with exposure to moisture and chemicals.

Ease of Installation: The threaded design of the M22 screw coupling makes it easy to install, as it doesn’t require specialized tools. This reduces installation time and labor costs, making it an ideal choice for applications that require quick setup or maintenance. For companies like Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd., which prides itself on delivering high-quality solutions, the ease of use and cost-effectiveness of the M22 coupling is a key selling point.

Leak Prevention: One of the most critical advantages of using M22 screw couplings is their ability to prevent leaks. The precise threading and the secure fit of the coupling ensure that liquids or gases remain safely contained within the system, even when under high pressure. This characteristic is essential in industries like automotive manufacturing, where fluid systems must operate without failure.

High Load Bearing: M22 couplings are designed to withstand heavy mechanical loads, making them suitable for use in high-stress environments. Their ability to bear large forces ensures that they perform reliably in industrial applications that demand robustness and stability. The high-strength design of the M22 screw coupling allows it to be used in machinery that experiences constant vibrations or requires resistance to impact forces.

Versatility: The versatility of the M22 screw coupling extends beyond its design. With the ability to be used in a variety of configurations—straight, elbow, or tee—this coupling is adaptable to numerous mechanical systems. This versatility allows industries such as agriculture, manufacturing, and automotive to leverage M22 couplings in diverse applications.

By focusing on continuous product improvement and using advanced manufacturing techniques, Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. ensures that all M22 screw couplings meet the highest quality standards. This dedication to excellence makes our couplings a trusted choice for businesses worldwide.

The versatility and durability of M22 screw couplings make them an indispensable component in many industries. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. has a deep understanding of these applications and provides M22 screw couplings to meet the needs of diverse sectors, each with unique requirements.

Automotive Industry: M22 couplings are widely used in the automotive sector for securing connections in fluid and gas systems. Whether for hydraulic systems, fuel lines, or exhaust components, the strength and leak-proof nature of M22 couplings ensure the safety and reliability of vehicles. As a manufacturer specializing in connectors and couplings, Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is committed to providing automotive suppliers with reliable M22 screw couplings that contribute to vehicle performance and safety.

Agricultural Machinery: In the agricultural industry, M22 screw couplings are commonly used in irrigation systems, fertilizer injectors, and farming equipment. Their resistance to environmental factors such as moisture and chemicals makes them perfect for the agricultural sector, where harsh conditions are the norm. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. manufactures M22 couplings that cater to the specific needs of agricultural machinery, ensuring that components stay securely connected under high-pressure and heavy-duty conditions.

Hydraulic Systems: The M22 screw coupling’s ability to maintain a tight seal under pressure makes it ideal for use in hydraulic systems, which often deal with high-pressure fluids. These couplings are integral to maintaining the integrity of hydraulic machinery, such as pumps, cylinders, and valves, by preventing leaks and ensuring system stability. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is known for producing M22 couplings that are trusted by industries requiring reliable hydraulic connections.

Industrial Equipment: In manufacturing plants and industrial settings, M22 screw couplings are commonly used to connect pipes, valves, and other components in fluid and gas systems. The ability to withstand mechanical stress and prevent leaks is essential in ensuring smooth operations and minimizing downtime. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. produces M22 screw couplings that meet the rigorous standards of industrial applications, allowing businesses to enhance their operational efficiency.

English

English русский

русский

0086-13003738672

0086-13003738672