Application Scope of Stainless Steel Spray Gun Barrels

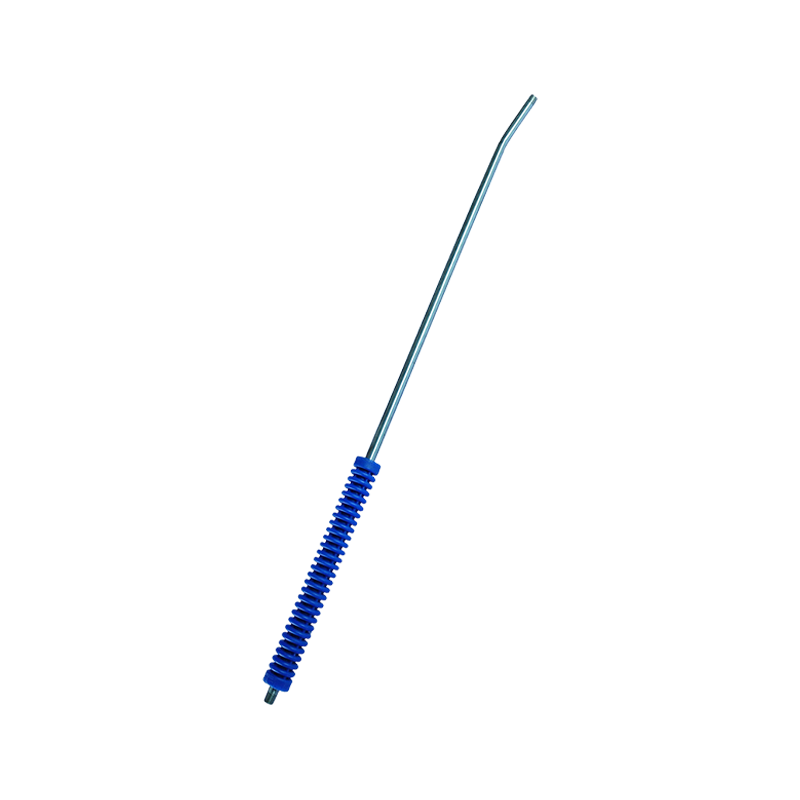

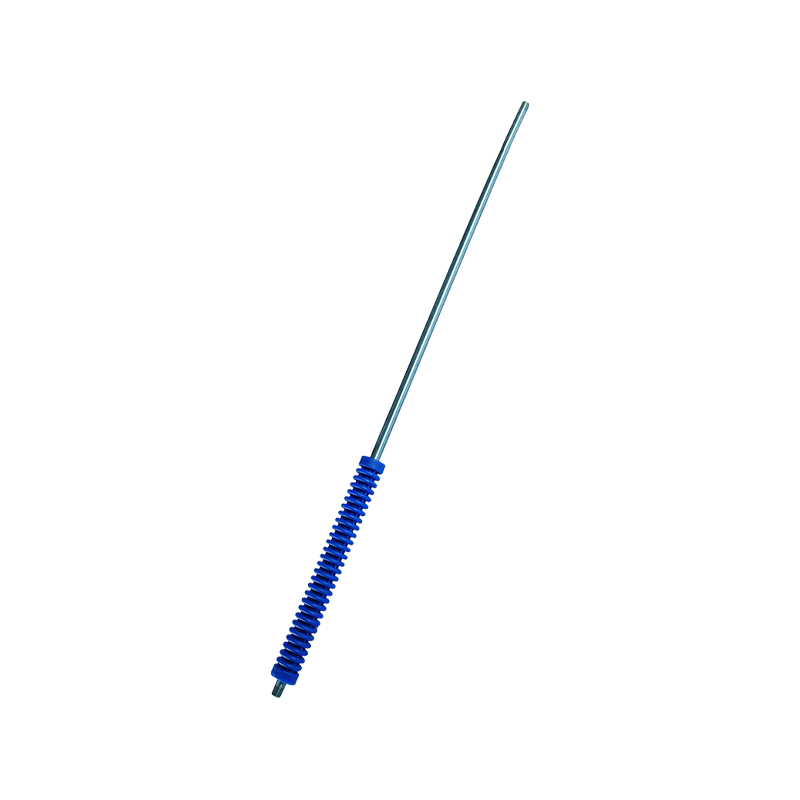

Stainless steel spray gun barrels are indispensable in agricultural operations where they are used to apply fertilizers, pesticides, herbicides, and fungicides with precision. The nature of agricultural chemicals demands that spray gun barrels resist corrosion and degradation over time. Stainless steel’s inherent resistance to rust and chemical attack ensures these barrels maintain structural integrity even after repeated exposure to harsh agrochemicals. This reliability is essential for farmers and agricultural workers who depend on consistent spray patterns for effective crop protection and yield enhancement. The mechanical durability of stainless steel allows the barrels to withstand rough handling and environmental factors such as exposure to sunlight, moisture, and dirt during field operations. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. produces spray gun barrels designed specifically to meet these rigorous demands, combining corrosion resistance with mechanical strength. Their products minimize downtime due to maintenance or replacement, enabling agricultural businesses to maintain continuous operations throughout planting and growing seasons. The company’s expertise in manufacturing ensures that the barrels’ internal surfaces are polished and smooth, which helps prevent clogging caused by chemical residues. This smoothness contributes to uniform spray dispersion, ensuring precise application of chemicals while reducing waste and environmental impact. In addition to durability, the barrels’ design allows compatibility with a wide range of agricultural spray guns and accessories, providing flexibility for users to tailor their spraying systems according to specific crop types and terrain conditions. Thus, stainless steel spray gun barrels are fundamental in supporting sustainable and efficient agricultural practices.

In industrial settings, cleanliness is not only a matter of aesthetics but also a critical factor influencing product quality, safety, and operational efficiency. Stainless steel spray gun barrels are vital components in high-pressure cleaning systems that remove contaminants such as oils, greases, dust, and chemical residues from machinery, production lines, and facility surfaces. The barrels must endure exposure to abrasive particles, harsh detergents, and hot water or steam without succumbing to corrosion or structural failure. Stainless steel’s robust nature allows spray barrels to maintain their shape and sealing capability even after prolonged use in aggressive environments. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. utilizes advanced manufacturing techniques to produce barrels that fulfill the exacting requirements of industries like automotive, pharmaceutical, and food processing, where hygiene and cleanliness standards are extremely high. Their barrels facilitate controlled spray pressures and patterns, enhancing the effectiveness of cleaning operations and reducing water and chemical consumption. The corrosion-resistant properties of stainless steel prevent contamination that could result from metal degradation, thus ensuring the cleanliness standards are not compromised. The durability of these barrels translates into fewer replacements, lowering overall operational costs and minimizing equipment downtime. Because industrial cleaning processes demand adaptability, the barrels from Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. are designed to be compatible with various spray gun models and can be integrated into automated cleaning systems. This flexibility supports diverse cleaning protocols and helps industries maintain compliance with safety and environmental regulations.

Chemical and petrochemical plants operate under challenging conditions where equipment components face continuous exposure to aggressive substances, including acids, alkalis, solvents, and hydrocarbons. Stainless steel spray gun barrels are essential in such environments for spraying chemicals safely and efficiently. The barrels must resist chemical corrosion while withstanding the high pressures necessary to deliver precise spray volumes and coverage. Stainless steel’s exceptional chemical resistance ensures that barrels do not deteriorate, preventing leaks or contamination that could compromise safety or product quality. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. manufactures barrels to rigorous standards, ensuring they meet the durability and reliability demands typical of chemical processing operations. The barrels’ design incorporates features to handle thermal fluctuations and mechanical stress caused by high-pressure spraying. Their seamless construction and smooth internal surfaces reduce the risk of buildup or clogging caused by chemical deposits, promoting consistent flow rates and spray patterns. This consistency is critical for applications such as neutralization, cooling, or coating processes within the petrochemical industry. By using stainless steel barrels from Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd., facilities enhance operational safety, reduce downtime caused by equipment failure, and ensure compliance with industrial regulations governing hazardous substance handling. The company’s ability to customize barrel dimensions and specifications further supports specialized spraying needs in complex chemical environments.

Municipal services demand equipment that can endure continuous use in diverse and sometimes harsh outdoor conditions. Stainless steel spray gun barrels are well-suited for applications such as street cleaning, sewer maintenance, firefighting, and public sanitation. These applications require spray barrels that resist corrosion from exposure to water, detergents, and environmental pollutants, as well as mechanical impacts from frequent handling and transport. Stainless steel provides the strength and longevity required for these demanding tasks, reducing the need for frequent replacements. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. produces barrels that maintain their structural integrity and functionality after extensive use in municipal operations. The barrels’ design supports high-pressure water delivery and efficient chemical dispersion, enabling effective cleaning of urban infrastructure and public spaces. Their corrosion resistance also prevents contamination of sprayed substances, maintaining environmental safety standards. The barrels are compatible with a range of spray gun systems used by municipal workers, facilitating quick attachment and detachment for maintenance or replacement. Stainless steel barrels support the use of eco-friendly cleaning agents and water recycling processes, aligning with modern environmental sustainability goals. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. ensures that their products are durable enough to withstand extreme weather conditions, from intense heat to freezing temperatures, making them reliable tools in all seasons.

The food and beverage industry requires rigorous hygiene and sanitation practices to prevent contamination and ensure product safety. Stainless steel spray gun barrels are integral to cleaning equipment that sanitizes processing lines, tanks, and storage facilities. Stainless steel’s non-porous surface resists bacterial adhesion and chemical corrosion, making it an ideal material for spray barrels used in washdown and clean-in-place (CIP) systems. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. supplies barrels that comply with industry hygiene standards, supporting food and beverage manufacturers in meeting regulatory requirements. The barrels are polished to a smooth finish, minimizing crevices where contaminants could accumulate. Their corrosion resistance allows them to tolerate frequent exposure to strong cleaning agents and hot water without degradation. The barrels also maintain dimensional stability and sealing performance under variable pressure and temperature conditions common in food processing environments. These features ensure consistent spray coverage, thorough cleaning, and reduced risk of cross-contamination between production batches. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. offers customizable barrels to suit specific equipment configurations and sanitation protocols, enhancing integration with automated cleaning systems. Their products help food and beverage companies uphold product quality, extend equipment lifespan, and optimize cleaning efficiency while safeguarding consumer health.

Precision and reliability are paramount in the automotive and aerospace industries, where spray guns equipped with stainless steel barrels are used for applying coatings, lubricants, and cleaning agents on complex components. These barrels must resist abrasion from particulate matter and chemical exposure while maintaining consistent spray patterns to meet stringent quality control standards. Stainless steel’s mechanical strength and corrosion resistance make it well-suited for these demanding environments. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. produces spray gun barrels engineered to exacting tolerances, enabling precise fluid delivery essential for surface treatment and maintenance operations. The barrels support high-pressure spraying and can be customized for specific thread sizes and lengths to fit specialized spraying equipment used in vehicle and aircraft manufacturing and repair. Their smooth internal finish ensures uninterrupted fluid flow, preventing clogging that could affect coating uniformity. By supplying durable barrels that maintain performance over extended cycles, Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. helps manufacturers reduce downtime, control coating quality, and meet safety regulations critical to aerospace and automotive sectors.

The maintenance of construction machinery and heavy equipment involves frequent cleaning and the application of protective coatings to prevent wear and corrosion. Stainless steel spray gun barrels provide the durability and resistance necessary to operate effectively in these harsh environments. They withstand mechanical impacts, dust, moisture, and abrasive particles encountered on construction sites. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd.’s barrels are designed to resist corrosion from exposure to lubricants, fuels, and cleaning solvents, ensuring long service life even under strenuous conditions. Their structural integrity allows for reliable high-pressure spraying, essential for removing hardened dirt and applying protective layers that extend equipment lifespan. The barrels’ compatibility with various spray gun models facilitates easy integration into maintenance workflows, enabling quick assembly and replacement to minimize operational downtime. The robust performance of these barrels supports the heavy-duty demands of construction and mining sectors, helping operators maintain equipment in optimal condition and reduce repair costs.

English

English русский

русский

0086-13003738672

0086-13003738672