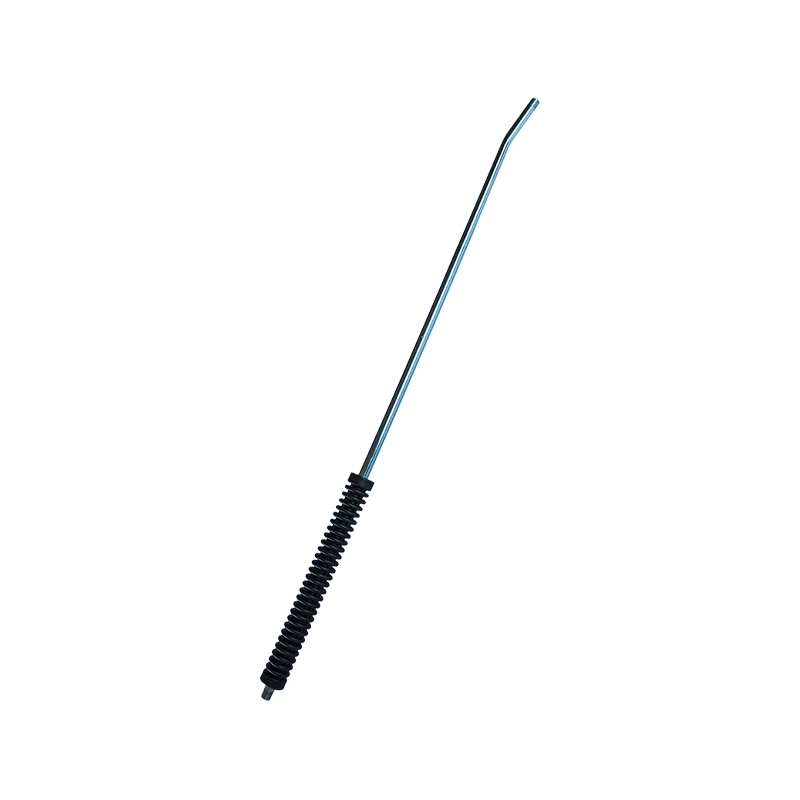

Performance Benefits of Chromed Steel Spray Gun Barrel in High-Pressure Cleaning Applications

The durability of a

Chromed Steel Spray Gun Barrel is primarily attributed to the combination of a high-strength steel substrate and the hard chrome plating applied to its surface. Steel itself provides the essential mechanical backbone, capable of withstanding significant internal pressures and mechanical stress without deformation. However, steel’s vulnerability to surface wear, abrasion, and corrosion necessitates additional protection. This protection comes in the form of a chromium plating layer, which is extremely hard and wear-resistant, significantly extending the barrel’s operational life. In high-pressure cleaning environments, barrels are constantly exposed to abrasive particles such as dirt, sand, and residues that flow through the barrel at high velocity. These particles, if not resisted, can cause micro-scratches or wear patterns that reduce barrel integrity and spray quality. The chromium coating provides a smooth, hard surface that resists such wear, preventing the barrel from becoming rough or damaged, which could disrupt fluid flow or weaken the structure. The manufacturing process involves advanced electroplating techniques, ensuring a uniform and consistent chromium layer, which minimizes weak spots that could lead to premature failure. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. utilizes cutting-edge equipment and strict quality control to maintain this consistency, which contributes to the reputation of their spray gun barrels as long-lasting and reliable components. This durability translates into fewer replacements, lower maintenance costs, and uninterrupted operation, making chromed steel barrels particularly suitable for industrial cleaning tasks where equipment downtime is costly.

Corrosion is a major threat to metal components used in cleaning equipment, particularly those exposed to water mixed with detergents, solvents, and sometimes acidic or alkaline chemicals. The Chromed Steel Spray Gun Barrel addresses this challenge effectively because the chromium plating forms a passive, highly corrosion-resistant barrier over the steel substrate. Chromium has the unique ability to oxidize superficially and form a very thin but tightly adherent chromium oxide layer, which protects the underlying metal from further chemical attack. This protective layer is extremely stable even in harsh environments, such as marine cleaning, chemical plant maintenance, and agricultural spraying where corrosive agents are frequently encountered. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. rigorously tests their chromed barrels to confirm resistance to various chemical exposures, including prolonged immersion in acidic or alkaline solutions. This attention to chemical resistance not only prolongs the barrel’s service life but also prevents contamination of the sprayed substances, which is critical in sensitive applications like food industry cleaning or pharmaceutical equipment maintenance. Corrosion resistance reduces the likelihood of cracks or leaks developing, which can pose safety hazards or reduce cleaning effectiveness. The chromed steel barrel ensures operational stability, safety, lower total ownership costs by resisting the chemically aggressive environments that are common in high-pressure cleaning applications.

The internal surface condition of a Chromed Steel Spray Gun Barrel plays a crucial role in determining the hydraulic performance of the entire spray system. A smooth, polished internal bore reduces fluid friction, enabling water or cleaning chemicals to flow with minimal resistance and turbulence. When flow resistance inside the barrel is minimized, more pressure energy is converted to kinetic energy at the nozzle, resulting in a stronger and more uniform spray jet. This improves cleaning efficiency by delivering water or chemical solutions more precisely and powerfully to the target surface. Conversely, barrels with rough or uneven internal surfaces cause fluid turbulence, pressure drops, and uneven spray patterns, reducing the effectiveness of cleaning operations. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. invests heavily in precision CNC machining and measurement systems to control internal diameters and surface finishes within tight tolerances. Their chromed barrels feature highly polished internal surfaces created by the electroplating process and subsequent finishing treatments, ensuring consistent flow characteristics. This is especially important in applications like automotive detailing or electronics cleaning, where uniform spray distribution and gentle but thorough cleaning are required. Efficient fluid flow also contributes to reduced energy consumption by the pump and system, as lower pressure losses mean less power is needed to achieve the desired spray intensity. Ultimately, the combination of precise internal dimensions and the smooth chrome finish helps optimize the hydraulic performance of cleaning systems equipped with Baige’s chromed steel spray gun barrels.

In high-pressure cleaning applications, barrels are subjected to intense internal forces that can cause deformation, fatigue, or catastrophic failure if the material and design are inadequate. The Chromed Steel Spray Gun Barrel benefits from the high tensile strength and toughness of steel, which allows it to contain pressures ranging from 1000 psi to well over 5000 psi safely. The hard chromium plating adds a further layer of protection against surface cracking or stress concentration points that might develop under cyclical loading conditions. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. ensures that every barrel is engineered to meet or exceed rigorous pressure requirements by performing detailed mechanical stress analyses and physical testing. This testing includes pressure cycling, burst testing, and impact resistance evaluations, all designed to validate the barrel’s capacity to maintain structural integrity under demanding operational conditions. The manufacturing process involves controlling microstructure and hardness of the steel substrate to optimize strength without compromising ductility, which helps absorb shock and sudden pressure spikes during use. The company’s investment in high-quality production equipment and skilled engineering teams ensures that their barrels have consistent mechanical properties batch after batch. The robust mechanical strength of Baige’s chromed steel barrels contributes directly to safety, reliability, and longevity, which are essential for professional cleaning operators working in industrial or commercial environments.

During extended operation, Chromed Steel Spray Gun Barrels may experience temperature rises caused by frictional forces of high-velocity fluids and the heat generated by pumps or chemical reactions within the cleaning solution. The barrel’s ability to resist thermal stress without distortion or damage is critical to maintaining tight dimensional tolerances and consistent spray performance. The chromium plating on these barrels exhibits excellent thermal conductivity and a low coefficient of thermal expansion relative to many other coatings, which helps distribute heat evenly and avoid localized hot spots that could cause cracking or warping. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. selects steel alloys and optimizes plating thickness to balance thermal and mechanical properties effectively. This approach maintains barrel roundness and bore consistency even after repeated thermal cycles, which is particularly beneficial for industrial degreasing, paint stripping, or chemical cleaning applications where heat and reactive chemicals coexist. The company’s manufacturing process includes thermal cycling tests to simulate field conditions, ensuring that the barrels can sustain operational temperatures without performance degradation. As a result, users experience fewer maintenance issues related to thermal damage, improved safety, and more reliable cleaning results throughout the lifespan of the spray gun barrel.

English

English русский

русский

0086-13003738672

0086-13003738672