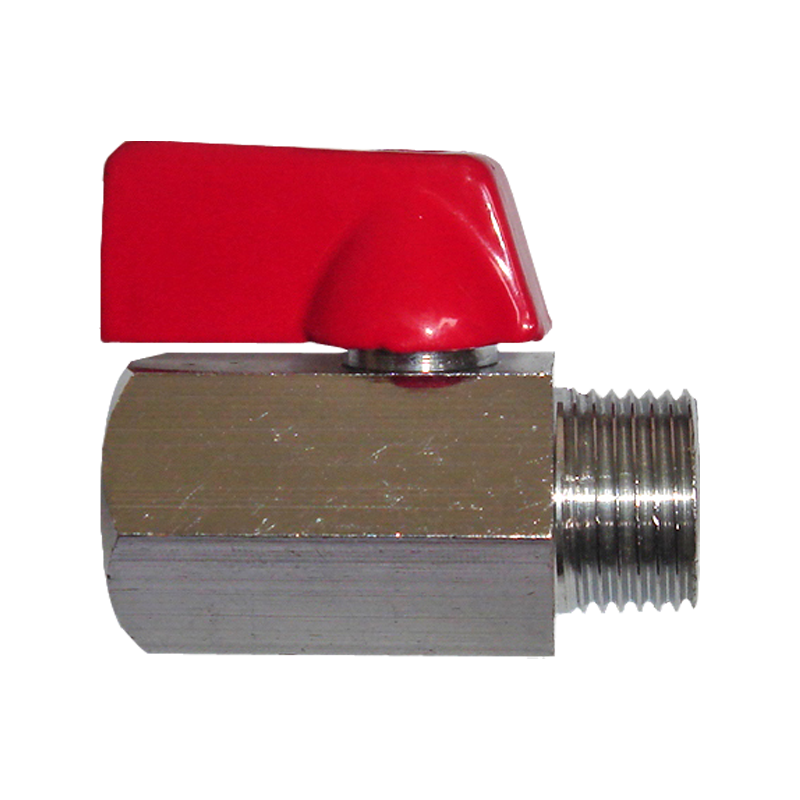

This Universal Manual Mini Ball Valve has a compact design and is suitable for a variety of industri...

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Power Washer Accessories Manufacturers and Other Cleaning Machine Accessories Factory, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

NEWS

-

What lubrication or assembly considerations are necessary to maintain smooth operation of the Ball Quick Coupling?

Importance of Proper Lubrication — Lubrication is a critical factor in ensuring the smooth engagement, disengagement, and overall reliability of a Ball Quick Coupling. The internal mechanism, including the ball lock system, sleeve, seals, and spring components, operates under high stress and frequ...

READ MORE -

What design features of the Weep Trigger Spray Gun prevent clogging or buildup during use with thick or particulate-laden liquids?

Wide-Bore Fluid Channels: The Weep Trigger Spray Gun incorporates fluid channels that are significantly wider than those found in standard spray guns, specifically designed to handle high-viscosity fluids and liquids containing particulate matter. The increased internal diameter reduces resistance...

READ MORE -

How does the Weep Trigger Spray Gun maintain spray consistency when used in high-pressure or high-volume industrial environments?

Precision Internal Valve and Fluid Control Mechanisms: The Weep Trigger Spray Gun utilizes a high-precision internal valve system engineered to regulate fluid flow accurately regardless of variations in input pressure. In high-volume or industrial environments, fluid supply pressure can fluctuate ...

READ MORE

Message Feedback

Industry Knowledge Extension

High-pressure cleaners not only rely on the output pressure and flow of the main machine, but also rely on the support of a variety of auxiliary accessories for high-performance cleaning effects. Although these accessories are inconspicuous, they are the key to achieving efficient, safe and precise cleaning operations. This article focuses on four typical cleaning machine accessories: Universal Manual Mini Ball Valve, Rotary Head, Y-Type Plastic Stop Valve and High Pressure Cleaner Lance Handle, and explains them in detail from multiple dimensions such as structural functions, technical characteristics, application scenarios, and selection recommendations.

Structure and Performance Characteristics

Compact Structural Design: One of the biggest advantages of mini ball valves is their highly integrated compact structure, which is especially suitable for pipeline systems with limited space. For example, in high-pressure cleaners, mobile cleaning platforms, experimental devices or compact industrial equipment, traditional ball valves are large in size and complex in connection, which is not conducive to layout optimization. Mini ball valves can be easily embedded in narrow spaces due to their compact overall structure, achieving high-density pipe layout, simplifying installation procedures, and greatly improving the efficiency and aesthetics of system wiring. The internal channel of the valve generally adopts a streamlined design or inner cavity polishing treatment, so that the fluid encounters less resistance during the passage process, reducing pressure loss and turbulence. For high-pressure water systems that need to maintain a stable flow rate and energy saving and high efficiency, this is an extremely critical performance improvement point.

Mini ball valves usually use three mainstream materials: stainless steel, brass, and high-performance plastics.

Stainless steel valve body: It has extremely high corrosion resistance, high pressure resistance and oxidation resistance, and is particularly suitable for demanding chemical fluid transportation, salt spray corrosion environment, and strong alkali and strong acid medium systems.

Brass valve body: It has good thermal conductivity and high strength, and is suitable for conventional water systems, oil media, and gas control scenarios. It is cost-effective and durable.

Engineering plastic valve body: It is light in weight, has strong acid and alkali resistance, and has excellent insulation performance. It can be used in corrosive liquid delivery systems or electronic/environmental protection fields.

The choice of material not only affects the stability and safety of the valve itself, but also directly affects the long-term reliability and subsequent maintenance costs of the entire system. High-quality materials mean that they can remain unchanged, leak-free, and unblocked under high temperature, low temperature, high pressure, and acid-base alternation conditions.

Manual quick opening/quick closing function: Another notable feature of the mini ball valve is that it has a 90-degree rotation quick opening and closing mechanism, that is, it only needs to rotate 1/4 turn clockwise or counterclockwise to complete the full opening or closing operation. This design greatly simplifies the user's operating difficulty of fluid control, especially when high-frequency switching or emergency shutdown of the system is required, it can respond quickly and stop the flow quickly to ensure the safety of the operation.

Application scenarios

Home cleaning and maintenance: In daily home use scenarios, mini ball valves are often installed at the front interface of cleaning equipment, such as between the faucet and the high-pressure spray gun, at the water outlet of the mobile car wash bucket, and at the garden pipeline joint. Its quick switching function allows users to use the spray gun or replace the nozzle without frequently turning off the main water source. Fluid control can be completed by rotating 90°. This convenience is especially suitable for daily household cleaning tasks where nozzles are frequently replaced and hose switching operations are frequent. In some household water tanks and garden irrigation systems, ball valves can also prevent backflow, stabilize water pressure, and regulate water volume. For example, when the user needs to stop spraying water for a short time, or temporarily shut down the water source to repair a section of the pipeline, the ball valve provides a fast, safe and precise flow cut-off node, which greatly improves the convenience of operation and the safety of water use.

Gas pipeline control: Mini ball valves also play an important role in pneumatic tools and compressed air systems. Especially in wind pressure cleaning systems, pneumatic nailers, and precision airflow blowing equipment, users often need to accurately control the airflow. At this time, the mini ball valve can be used as a branch regulating valve or a gas source quick disconnect device to achieve instant control of flow and pressure. Because its valve core has a smooth opening and closing action and strong sealing, it can withstand air pressure shocks within a certain range, and is not prone to air leakage or pressure attenuation. It is suitable for scenes with fast start and stop, frequent repetition, and compact space. In addition, its body material has good low temperature resistance and wear resistance, and can stably operate in different environments such as air conditioning pipelines, compressed air recovery systems, and mobile blowing equipment.

Chemical cleaning equipment: In the fields of industrial cleaning, environmental water treatment, food disinfection, laboratory liquid preparation, etc., mini ball valves are often used as delivery valves for corrosive fluids or high-concentration detergents. Its integrated small-volume design makes it easy to install in limited spaces such as the diversion port, the bottom of the liquid storage tank, and the front end of the mixing nozzle in the pipeline system. Users can manually adjust the opening angle of the ball valve to accurately control the liquid discharge speed of the cleaning agent to prevent corrosion risks caused by excessive use or local over-concentration.

System working principle

The Rotary Head is the core component of the flat disc floor scrubber. The structure includes a rotating central shaft, a driving pin, and a water outlet. High-pressure water is introduced through the central shaft, driving the connecting rod or arm-shaped nozzle to rotate at high speed, while spraying high-pressure water to form a cleaning impact on the ground.

Rotating center axis: connects the spray bar and the spray disc, is the core axis of the whole rotating system, responsible for introducing water flow from the top and transmitting it to the rotating spray arm at the bottom;

Drive pin: connects the center axis and the spray arm assembly, converts linear pressure into rotational torque under the action of high-pressure water flow;

Rotating spray arm: usually in a "T" or "L" structure, with angled nozzles at both ends, which can form a spiral cleaning track when rotating;

High-pressure water outlet: located at both ends of the rotating spray arm, the spray water flow has an angled design to provide rotational force and hit dirt;

Seal and bearing system: used to withstand high pressure, water flow impact and high-speed rotation friction to ensure stable operation of the system without leakage.

Structural details advantages

High-pressure seal: the center axis is made of stainless steel, and the shaft seal is precisely designed to ensure no leakage under high pressure of tens to hundreds of megapascals;

High-speed operation wear-resistant: with impact-resistant bearings inside, the spray arm can still operate smoothly at thousands of revolutions per minute;

Lightweight aluminum shell: aluminum alloy or titanium alloy shell, taking into account strength and weight, strong corrosion resistance.

Application areas

Parking lot/factory floor: In underground parking lots, manufacturing workshops, logistics warehouses and other environments, the ground is often repeatedly contaminated by tire friction, mechanical oil stains, metal chips and dust and dirt for a long time, making it difficult to clean. Rotary Head can provide a strong high-pressure rotating water flow to quickly remove stubborn dirt, especially in areas with heavy oil pollution. Compared with traditional manual brushing methods, this equipment can greatly improve work efficiency and reduce labor fatigue. It is an indispensable cleaning tool in the maintenance of industrial and commercial facilities.

Tunnel/airport runway cleaning: The cleaning requirements of tunnels and airport runways are not only reflected in the decontamination ability, but more importantly, the high-efficiency coverage and continuous operation capabilities of large areas. Rotary Head can cooperate with high-pressure cleaning vehicles to achieve synchronous high-pressure rotary cleaning of the runway or tunnel inner surface during high-speed driving, which not only increases the cleaning area per unit time, but also ensures uniform and no omissions in cleaning, meeting the special needs of airports and urban tunnels for "fast cleaning speed and no impact on traffic scheduling".

Cleaning of public places: such as municipal squares, commercial streets, sidewalks, subway entrances and exits, where there are dense crowds of people every day, it is very easy for footprints, oil stains, food residues and other pollutants to remain on the ground. Such places are mostly paved with stone, cement bricks or other hard surfaces, which puts forward dual requirements on the efficiency of cleaning equipment and the ability to protect the ground. Rotary Head outputs high-pressure water flow through stable rotation, effectively improving the cleaning efficiency per unit time, quickly removing stubborn stains, and at the same time will not damage the surface of the floor material. It is one of the important equipment for modern urban environmental cleaning.

English

English русский

русский

0086-13003738672

0086-13003738672