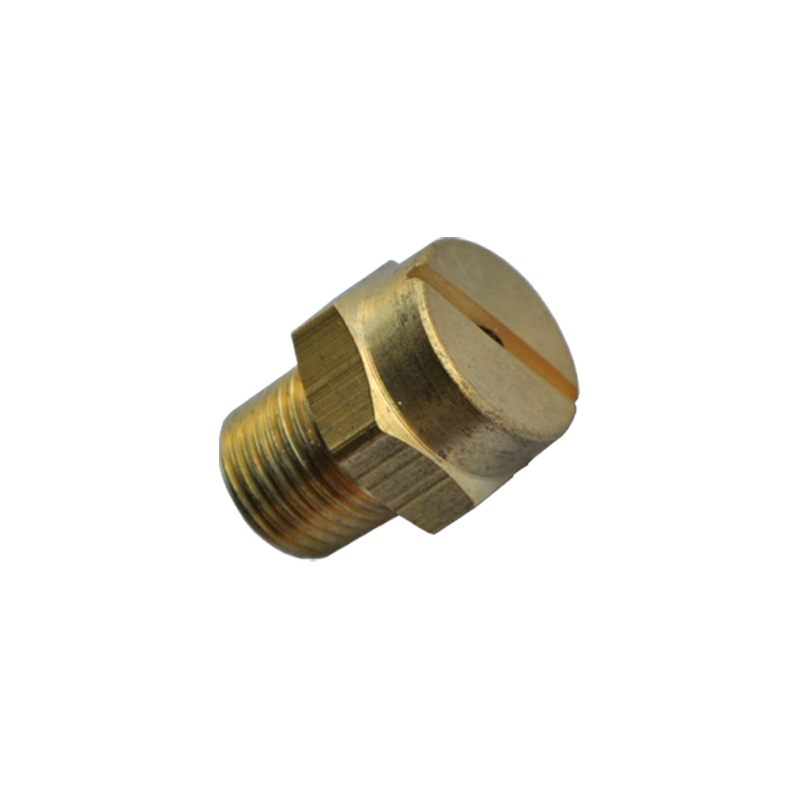

The Meg Threaded Soap Brass Nozzle is a high-quality nozzle designed to provide consistent and effic...

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Chemical Nozzle Manufacturers and Chemical Nozzle Suppliers, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

NEWS

-

What lubrication or assembly considerations are necessary to maintain smooth operation of the Ball Quick Coupling?

Importance of Proper Lubrication — Lubrication is a critical factor in ensuring the smooth engagement, disengagement, and overall reliability of a Ball Quick Coupling. The internal mechanism, including the ball lock system, sleeve, seals, and spring components, operates under high stress and frequ...

READ MORE -

What design features of the Weep Trigger Spray Gun prevent clogging or buildup during use with thick or particulate-laden liquids?

Wide-Bore Fluid Channels: The Weep Trigger Spray Gun incorporates fluid channels that are significantly wider than those found in standard spray guns, specifically designed to handle high-viscosity fluids and liquids containing particulate matter. The increased internal diameter reduces resistance...

READ MORE -

How does the Weep Trigger Spray Gun maintain spray consistency when used in high-pressure or high-volume industrial environments?

Precision Internal Valve and Fluid Control Mechanisms: The Weep Trigger Spray Gun utilizes a high-precision internal valve system engineered to regulate fluid flow accurately regardless of variations in input pressure. In high-volume or industrial environments, fluid supply pressure can fluctuate ...

READ MORE

Message Feedback

Industry Knowledge Extension

Application of polypropylene (PP) materials in chemical nozzles

Polypropylene materials have good chemical stability and can maintain strong corrosion resistance in most weak acid and weak alkali environments. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. uses PP materials in some mildly corrosive liquid delivery nozzles, mainly for agricultural spraying, basic daily chemical spraying or detergent distribution. PP materials have good processing and molding properties, relatively low cost, suitable for mass production, while maintaining a relatively stable physical structure. The low density of this material also makes the nozzle lighter as a whole, easy to carry and operate.

Selection of polytetrafluoroethylene (PTFE) materials under highly corrosive media

Polytetrafluoroethylene, also often called Teflon, is one of the most widely used corrosion-resistant polymer materials. It is characterized by almost no reaction with any acid or alkali, and is particularly suitable for conveying highly corrosive media such as concentrated sulfuric acid, concentrated hydrochloric acid, and hydrofluoric acid. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. uses PTFE materials as linings or main shells in high-protection grade nozzles for the chemical industry, especially for high-demand working environments. Although the processing difficulty is relatively large, PTFE materials can effectively extend the service life of nozzles and reduce the safety hazards caused by corrosion.

Neutral corrosion protection performance of polyethylene (PE) materials

Although the chemical stability of polyethylene materials is not as good as PTFE, they still have certain corrosion resistance under neutral cleaning fluids and some oxidants. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. introduces PE materials into some economical chemical nozzles according to actual use needs, which are suitable for application scenarios where the material requirements are not too strict but basic corrosion protection is required. For example, daily surface dust removal and kitchen degreaser spraying belong to this category. PE materials have good flexibility and can buffer internal liquid pressure within a certain range to reduce the risk of nozzle rupture.

Stainless steel materials as a reinforcement option for structural parts and key contact parts

Although stainless steel is not a polymer material, its performance in high-strength and anti-rust occasions is still widely accepted. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. often uses 304 or 316 stainless steel as key parts such as threaded interfaces, sealing connectors and reinforcing ribs in the design of multifunctional chemical nozzle structures to improve overall strength and connection reliability. Molybdenum is added to 316 stainless steel, and its corrosion resistance is better than 304 material in chloride environment, which is suitable for salt spray or marine working conditions.

Balancing application of composite structure between corrosion resistance and strength

As users put forward higher requirements for the functions of chemical nozzles, Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. has also been trying to introduce composite structures into its products. For example, the shell is made of PP material to reduce weight, while the inner core or nozzle hole of the nozzle is made of PTFE or 316 stainless steel to enhance corrosion protection and mechanical strength. This structure can not only ensure the light operation of the nozzle, but also adapt to the needs of spraying a variety of chemical liquids, improving the overall practicality.

Material selection needs to be combined with the specific application environment

The material selection of chemical nozzles is not a single standard, but needs to be comprehensively evaluated according to the type, concentration, temperature and working environment of the chemical liquid sprayed. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. will provide a variety of material recommendations and sample comparison test plans in the process of docking with customers to help users choose a more suitable nozzle structure and material configuration to ensure that it operates more stably and safely in actual working conditions.

Reasonable selection of corrosion-resistant materials

Material is the primary factor that determines the service life of chemical nozzles. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. uses polypropylene (PP), polytetrafluoroethylene (PTFE), polyethylene (PE) and 316 stainless steel for structural combination according to the characteristics of different spraying media. For example, PTFE is suitable for highly corrosive chemical liquids, while 316 stainless steel is suitable for use in chloride-containing cleaning liquids. Tailoring materials according to the use environment can effectively reduce the wear or corrosion of the nozzle caused by chemical reactions, thereby extending its service life.

Optimize nozzle structure design

In addition to the material itself, the structural design of the nozzle also directly affects its durability. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. focuses on the streamline design of the internal channel during the development of the nozzle, and tries to avoid dead corners and sharp corners to reduce the possibility of liquid retention and local corrosion. At the same time, for operating environments that require frequent replacement, the company adds a detachable structure to the product design to facilitate cleaning and maintenance, and also avoid blockage or wear caused by long-term fouling.

Improve the precision of the manufacturing process

The manufacturing process plays a key role in the stability of product quality. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. has introduced a number of high-precision injection molding and CNC processing equipment to standardize the control of each contact surface, inner hole and threaded part of the nozzle. Through the precision manufacturing of the mold and the automated injection molding technology, not only the consistency of the product is improved, but also the early loss caused by excessive product tolerance is avoided.

Implement targeted surface treatment

On metal nozzle parts such as stainless steel, surface treatment can significantly improve durability. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. uses electropolishing, sandblasting, passivation and other methods to treat the metal surface according to different usage requirements, making it smoother and denser, and reducing the adsorption of micro cracks to corrosive media. In addition, some models can further enhance their chemical corrosion resistance through fluorinated coatings to adapt to a wider range of application scenarios.

Regular maintenance and correct use methods

The daily use and maintenance frequency of the product also affect its service life. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. recommends that users regularly disassemble and clean the nozzle in after-sales service to avoid long-term accumulation of chemical residues in the nozzle cavity. For equipment that is exposed to a strong corrosive environment for a long time, it is recommended to configure a filtration system or flush it with a neutral liquid to reduce the nozzle load. At the same time, before switching between different liquids, doing a good job of material compatibility testing in advance can also help prevent the material from aging too quickly.

Establish product usage records and replacement cycles

To facilitate users to manage the nozzle usage cycle, Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. encourages customers to establish archive records for nozzle products, including information such as the first activation time, daily usage time, and spraying liquid types. By accumulating data, a reasonable replacement cycle recommendation is gradually formed, so as to achieve early prediction and preventive maintenance, and avoid systematic losses caused by nozzle aging.

Provide supporting components to enhance the overall performance of the system

The durability of the nozzle is not only a problem of its own structure, but also closely related to the matching degree of the system accessories. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. provides products such as quick connectors, sealing gaskets, filters and hose assemblies for use with chemical nozzles. The design of these accessories is developed based on the principle of material compatibility, reducing the damage to the nozzle caused by leakage of the pipeline interface or high-pressure impact, and effectively improving the stability of the entire system.

English

English русский

русский

0086-13003738672

0086-13003738672