The trolley foam nebulizer is a mobile device that integrates advanced foam atomization technology a...

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Foam Detergent Nebulizer Manufacturers and Foam Nebulizer Suppliers, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

NEWS

-

What lubrication or assembly considerations are necessary to maintain smooth operation of the Ball Quick Coupling?

Importance of Proper Lubrication — Lubrication is a critical factor in ensuring the smooth engagement, disengagement, and overall reliability of a Ball Quick Coupling. The internal mechanism, including the ball lock system, sleeve, seals, and spring components, operates under high stress and frequ...

READ MORE -

What design features of the Weep Trigger Spray Gun prevent clogging or buildup during use with thick or particulate-laden liquids?

Wide-Bore Fluid Channels: The Weep Trigger Spray Gun incorporates fluid channels that are significantly wider than those found in standard spray guns, specifically designed to handle high-viscosity fluids and liquids containing particulate matter. The increased internal diameter reduces resistance...

READ MORE -

How does the Weep Trigger Spray Gun maintain spray consistency when used in high-pressure or high-volume industrial environments?

Precision Internal Valve and Fluid Control Mechanisms: The Weep Trigger Spray Gun utilizes a high-precision internal valve system engineered to regulate fluid flow accurately regardless of variations in input pressure. In high-volume or industrial environments, fluid supply pressure can fluctuate ...

READ MORE

Message Feedback

Industry Knowledge Extension

A foam detergent nebulizer, also known as a foam sprayer or foam generator, is a cleaning device that uses physical or pneumatic methods to mix detergent with air to generate stable foam and evenly spray it on the target surface. Compared with traditional spray bottles or liquid atomizers, foam atomizers can keep foam attached during spraying, extend the foam residence time, improve the cleaning penetration effect, reduce the amount of chemical agents, save energy and water, and improve efficiency.

Core functions include:

1. Mixing and foaming of liquid and air to form fine foam

The basic function of the foam detergent nebulizer is to fully mix the liquid detergent with air, shear and turbulence through the foaming core, so as to form foam with uniform size and stable structure. This process not only improves the efficiency of the detergent, but also makes the foam have stronger adhesion and covering ability after spraying.

The diameter of high-quality foam is generally between 20–200μm. The smaller and more delicate it is, the deeper it can penetrate into fine cracks and texture surfaces, wrap the pollution source, soften stubborn stains, and form an efficient cleaning effect. This foaming process is essentially a gas-liquid two-phase flow control technology, which has fine requirements on parameters such as air pressure ratio, flow regulation, and nozzle diameter, and is one of the core indicators of product performance.

2. Uniform atomization spraying to ensure coverage and permeability

In addition to generating foam, another key function of the foam atomizer is how to spray the foam evenly on the surface to be cleaned. Through a specially designed nozzle, the equipment can finely atomize the foam and output it, so that the foam layer can be evenly spread on various structures such as walls, pipes, and equipment surfaces.

This "atomization + foaming" composite spraying form is far superior to the point or drop spraying effect of traditional liquid spray pots. It can achieve a coverage rate of more than 90%, especially in high places, dead corners, gaps and other areas. It can also achieve effective adhesion, improving the comprehensiveness and efficiency of the entire cleaning process.

3. Improve the adhesion of foam, suitable for facades, concave and convex structures and vertical attachment scenes

The foam has a strong "wall hanging property" - that is, it will not slide off quickly after being attached to a vertical or irregular surface. This ability enables foam atomizers to show great advantages in three-dimensional cleaning scenarios such as columns, walls, round pipes, equipment gaps, and rough components.

Compared with liquid cleaning agents, foams have a longer retention time, allowing active substances to fully contact dirt and effectively soften and emulsify grease, dirt, or carbon stains.

At the same time, strong adhesion can also prevent the rapid loss of cleaning fluid and increase the duration of drug efficacy, thereby reducing secondary spraying and repeated scrubbing, saving manpower and time costs.

4. Reduced volume treatment, reducing detergent consumption and environmental emissions

During the mixing and spraying process, the foam atomizer can achieve an efficient cleaning effect after dilution. For example, traditional cleaning methods may require a detergent concentration of 1:10, while the foam system can often achieve the same effect with a dilution of 1:30 or even 1:50 through air expansion and improved adhesion.

1. Structural components

A typical foam detergent nebulizer consists of the following parts:

Pot body/container: The pot body or container is the basic part of the whole device. Its function is not only to hold the foam cleaning liquid, but also has a capacity scale for accurately mixing the ratio of cleaning liquid to water, so that the foam concentration is always kept within the ideal range. Some professional-grade containers are also designed with acid and alkali resistance, high compressive strength, and transparent observation windows, which are convenient for operators to carry out daily maintenance and liquid level monitoring.

Liquid inlet pipe: The liquid inlet pipe is the conveying channel between the pot body and the foaming system, responsible for accurately introducing the prepared cleaning liquid into the foaming chamber. A high-quality liquid inlet pipe should not only have good chemical corrosion resistance, but also be flexible and stable to avoid problems such as kinking and breaking during use that affect the liquid delivery efficiency. At the same time, a micro filter will be installed at the bottom of some liquid inlet pipes to effectively prevent impurities from entering the foaming system and causing blockage.

Foaming core: The foaming core is the key unit for foam formation, often composed of stainless steel metal mesh, foam cotton or plastic foam. The cleaning liquid and air are fully mixed here, and shear and emulsify through the pores and structures on the surface of the core, thereby generating foam with uniform structure and moderate density. Different foaming core materials have a significant impact on the fineness, adhesion and duration of foam particles. Therefore, in high-demand application scenarios, the selection of foaming media is particularly critical.

Air input system: The air input system is the power source for foam atomization, responsible for providing the necessary airflow to drive the mixing of cleaning liquid and air. Depending on the type and purpose of the atomizer, this part can be a manual pressurizing device, an external air pressure pipeline system, or a built-in fan or micro-electric pump. The system must have a stable air supply, and the air pressure directly affects the foaming rate, spraying distance and spraying angle of the foam. High-end equipment often supports multi-speed air pressure adjustment to ensure the best effect in different use environments.

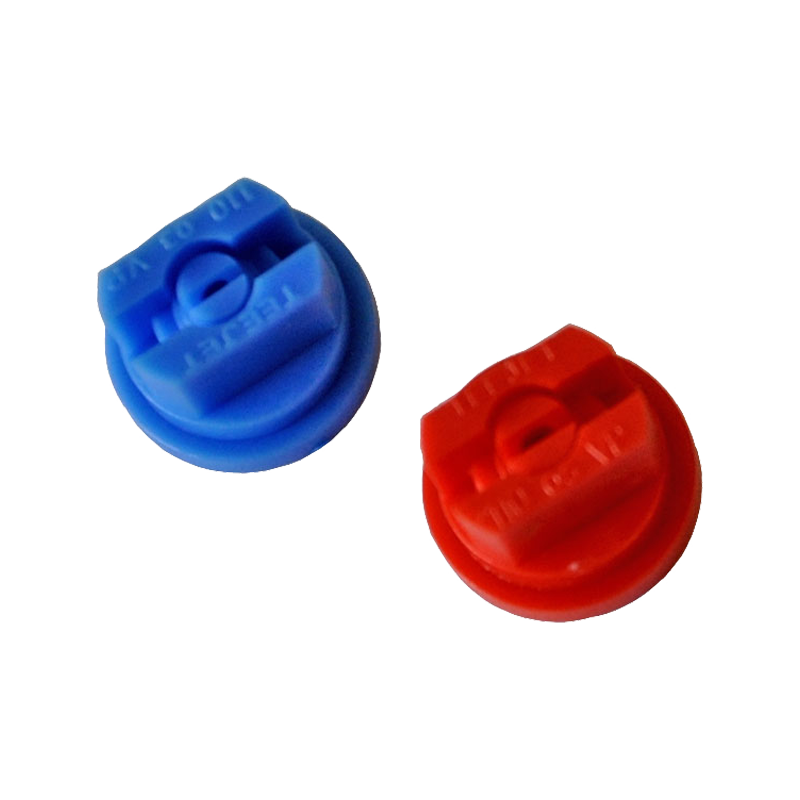

Nozzle assembly: The nozzle assembly is the final outlet of the foam, and its structure and shape determine the spraying method and coverage of the foam. Depending on different uses, it can be configured as a fan nozzle, a cylindrical straight nozzle or a composite nozzle with a rotating spraying function. The nozzle material is mostly made of corrosion-resistant plastic or stainless steel to ensure that it can remain unobstructed and accurate even in the case of long-term contact with chemical cleaning agents. The scientifically designed nozzle can atomize the foam into fine and uniform particles to achieve more comprehensive coverage and penetration.

Pressure or liquid volume regulating valve: The pressure or liquid volume regulating valve is used to accurately control the pressure and flow of the cleaning liquid spray, and is a key component that affects the foam concentration, spraying intensity and economic use. The regulating valve can flexibly adjust the foam spray volume according to the needs of different cleaning objects and operating scenarios, so that the foam does not waste resources due to excessive use, nor does it affect the cleaning effect due to insufficient use. Some advanced atomizers are also equipped with digital pressure gauges and knob-type fine-tuning structures to improve the convenience and accuracy of control.

Connectors: The connector part mainly includes quick connectors, universal joints, threaded adapters, etc., which are responsible for effectively connecting the foam atomizer with other equipment such as high-pressure water guns, pipeline systems, safety valves, etc. These connecting parts must be structurally pressure-resistant and leak-proof, and have quick disassembly and assembly functions, so that users can quickly switch equipment, perform maintenance or replace accessories between different cleaning tasks, thereby improving overall work efficiency and user experience.

2. Atomization and foaming mechanism

After the liquid enters the foaming chamber, it will be fully sheared and mixed with the air at the foaming core. The structural design of the foaming core usually has a multi-layer mesh or porous material. These tiny pores and complex channels can effectively stir and shear the liquid and air repeatedly in a very small space, so that the two can be fully integrated to form a preliminary foam mixture. This process plays a decisive role in the fineness and stability of the foam, because only foam that has been efficiently mixed and sheared can form tiny bubbles with uniform texture and strong adhesion.

These mixed foams are atomized and sprayed through precisely designed nozzles. The size and structural design of the nozzle are crucial and directly affect the particle size and spray form of the foam. The width of the flow channel inside the nozzle, the shape of the outlet and the pressure distribution will affect the spray effect. By adjusting the nozzle caliber, the conversion of the spray from coarse particles to fine foam can be achieved to meet the needs of different cleaning scenarios.

The ratio control between air flow rate and liquid flow rate is the key parameter of foam particle size. Appropriate air flow rate can cut the liquid into smaller foam particles, increase the surface area and adhesion ability of the foam. On the contrary, if the air flow rate is too low or the liquid flow is too large, the foam particles will become coarse, the adhesion will decrease, and the spraying effect will be poor. Therefore, the reasonable regulation of the flow rate ratio of the two can ensure that the foam is both fine and durable, and achieve the best cleaning and coverage effect.

Overall, a good atomizer can generate foam with strong adhesion, fine particles and uniform coverage, which not only improves the utilization efficiency of the detergent, but also makes the cleaning process more efficient and environmentally friendly. Through the evenly distributed foam layer, the detergent can penetrate into the surface and concave and convex details of the cleaning object, improve the effect of stain softening and removal, and reduce the waste of chemical agents and environmental pollution, so as to achieve the goal of energy saving and emission reduction.

Foam detergent nebulizer has penetrated into many industry scenarios that attach great importance to cleaning and hygiene:

Car beauty and car washing: In the car beauty industry, foam atomizers are widely used in the pre-cleaning and fine washing stages of vehicle surfaces. Traditional car washing methods usually rely on manual scrubbing, which can easily cause problems such as scratches on the car paint and incomplete cleaning.

Industrial equipment and floor cleaning: In industrial environments, especially food processing plants, machinery manufacturing workshops, packaging workshops, etc., there are a large number of surfaces that need to be regularly degreased, sterilized, and dusted. Foam cleaning liquid atomizers can achieve targeted decontamination, wide ground coverage, reduce manual labor intensity, and ensure operational safety.

Kitchen and food industry: The kitchen is a key area where oil pollution is concentrated, and high-temperature smoke and water vapor make it difficult for ordinary cleaning methods to maintain long-term cleaning. Foam atomizers have become a catering cleaning tool with their delicate foam spraying capabilities, achieving efficient degreasing, reducing chemical usage, adapting to food-grade detergents, and improving operational efficiency.

Medical and public disinfection: With the improvement of public health awareness, hospitals, schools, transportation hubs and other spaces have higher requirements for disinfection efficiency. Foam atomizers can atomize disinfectant into lightweight foam to achieve rapid coverage, improve sterilization time, save disinfectants, and avoid secondary pollution.

Agricultural fruit trees/greenhouse spraying: In the process of spraying in orchards and greenhouse agriculture, traditional spraying often has problems such as pesticide splashing and wind loss. Foam atomization technology can improve adhesion, reduce liquid waste, and enhance insect repellent effect.

Exterior wall/epidemic prevention space spraying: Disinfectant foam spraying on building exterior walls, sewers, and public areas can hold highly fluid foam and prolong the action time of the liquid.

English

English русский

русский

0086-13003738672

0086-13003738672