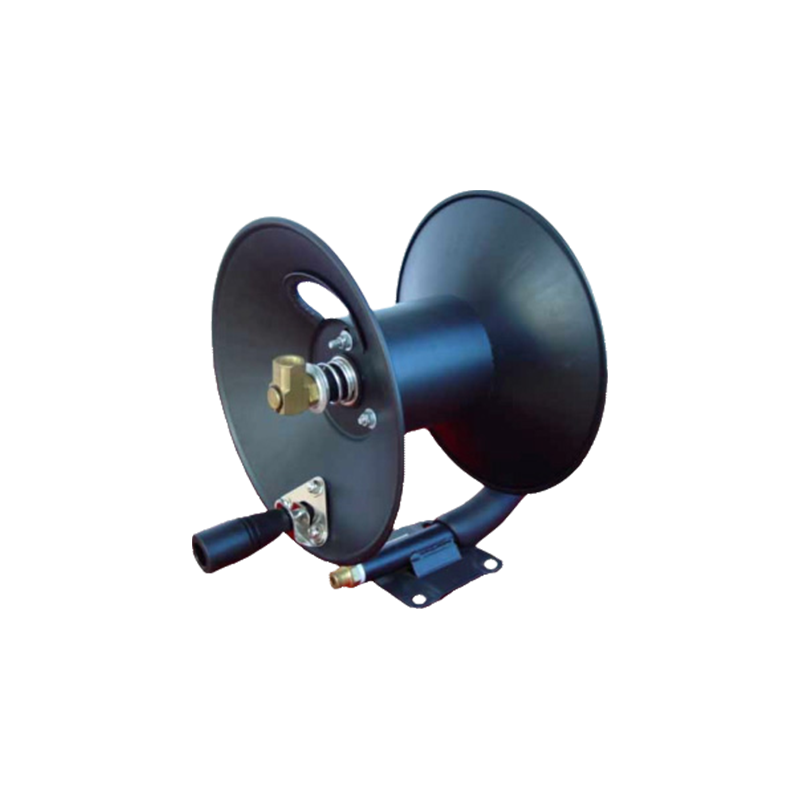

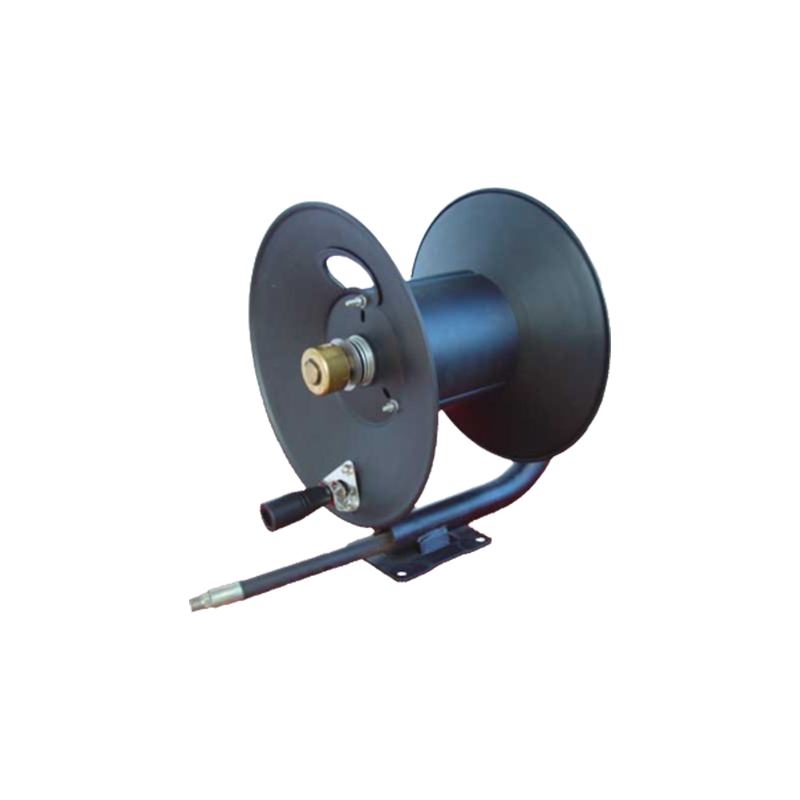

The High Pressure Washer Hose Reel is an accessory designed specifically for high-pressure cleaning ...

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Pressure Washer Hose Reel Manufacturers and Hose Reel Suppliers, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

NEWS

-

What lubrication or assembly considerations are necessary to maintain smooth operation of the Ball Quick Coupling?

Importance of Proper Lubrication — Lubrication is a critical factor in ensuring the smooth engagement, disengagement, and overall reliability of a Ball Quick Coupling. The internal mechanism, including the ball lock system, sleeve, seals, and spring components, operates under high stress and frequ...

READ MORE -

What design features of the Weep Trigger Spray Gun prevent clogging or buildup during use with thick or particulate-laden liquids?

Wide-Bore Fluid Channels: The Weep Trigger Spray Gun incorporates fluid channels that are significantly wider than those found in standard spray guns, specifically designed to handle high-viscosity fluids and liquids containing particulate matter. The increased internal diameter reduces resistance...

READ MORE -

How does the Weep Trigger Spray Gun maintain spray consistency when used in high-pressure or high-volume industrial environments?

Precision Internal Valve and Fluid Control Mechanisms: The Weep Trigger Spray Gun utilizes a high-precision internal valve system engineered to regulate fluid flow accurately regardless of variations in input pressure. In high-volume or industrial environments, fluid supply pressure can fluctuate ...

READ MORE

Message Feedback

Industry Knowledge Extension

Generally, the high-pressure washer hose reel is mainly composed of the following parts:

Shell and support frame: The shell and support frame of the hose reel are the core load-bearing structures of the entire system. Most of them are made of high-strength steel plates through bending and welding, or aluminum alloy die-casting technology to ensure excellent pressure resistance and corrosion resistance. Some products also use thick-walled engineering plastics or stainless steel materials to reduce weight and prevent rust. In terms of installation methods, they are usually divided into wall-mounted, floor-standing, and portable mobile types. Its structural design determines the overall stability, safety and scope of application.

Reel shaft and spring traction: The core movement mechanism of the reel is the bearing and spring assembly. The bearing supports the reel to rotate through the central axis to ensure smooth and smooth retraction and release. The automatic retraction spring system is usually arranged inside the reel or in the side cavity, and the hose can be automatically and gently retracted after use through the preset tension. The strength and durability of the spring directly affect the reeling speed and life. High-quality products use high-carbon steel manganese alloy springs with a recycling life of more than tens of thousands of times. This function greatly improves the operating efficiency, reduces the labor intensity of manual winding, and reduces the probability of hose wear due to mopping knots.

Limiting device and brake system: To prevent the hose from slipping excessively or rebounding automatically during the pulling process, the reel is usually designed with a limiting tooth or a spring-type brake device. The user can manually or automatically lock the hose length at the appropriate position to ensure the stability of the operation. Some high-end models are also equipped with a magnetically controlled limiting system or a friction damping structure, which can achieve a soft start/slow stop effect to prevent the high-pressure hose from rebounding and injuring people during rapid recovery. The reasonably designed limiting brake structure not only improves the flexibility of operation, but also enhances the overall safety performance.

Rotary joint: To prevent the hose from slipping excessively or rebounding automatically during the pulling process, the reel is usually designed with a limiting tooth or a spring-type brake device. The user can manually or automatically lock the hose length at the appropriate position to ensure the stability of the operation. Some high-end models are also equipped with a magnetically controlled limiting system or a friction damping structure, which can achieve a soft start/slow stop effect to prevent the high-pressure hose from rebounding and injuring people during rapid recovery. The reasonably designed limit brake structure not only improves the flexibility of control, but also enhances the overall safety performance.

Quick connector interface: As the hub component connecting the water source and the reel, the swivel joint is located at the axis of the reel. Its greatest function is to achieve continuous transmission of water flow during the rotation of the hose around the reel. This part needs to withstand high-pressure water flow while maintaining a 360-degree rotation seal, so its material is mostly brass, stainless steel or alloy steel, and is equipped with high-pressure resistant O-rings and sealing gaskets inside. High-quality swivel joints not only reduce the fatigue fracture of the hose caused by winding, but also ensure the pressure stability and flow continuity of the entire system during operation.

Hose storage groove and guide wheel: The inlet and outlet interfaces of the reel are usually designed as standardized quick connectors, such as G1/4, G3/8, M22 and other specifications, which are convenient for seamless connection with high-pressure pumps, spray guns, extension rods and other components of different brands. High-quality connectors are usually made of nickel-plated brass or stainless steel, which are not only resistant to high pressure and corrosion, but also have good leak-proof performance. Some models also integrate pressure regulating valves, check valves or filters to further improve the system adaptability and water quality control capabilities to ensure the cleaning effect.

Prevent hose damage and extend life. When used outdoors, high-pressure hoses are often faced with challenges such as ground friction, mechanical pulling, frequent bending, and exposure to ultraviolet radiation and acid-base corrosion in the natural environment. These factors can easily cause wear, cracks, and even bursts on the surface of the hose, greatly shortening the service life of the hose. The reel stores the hose in an orderly manner, avoiding direct contact with the ground and random dragging, effectively preventing the hose from being damaged by grinding, collision with sharp objects, and excessive bending, fundamentally improving the durability of the hose. The automatic retraction spring and guide wheel system work together to ensure that the tension of the hose is reasonable during the retraction process, further reducing internal structural fatigue and external physical damage, and significantly extending the service life.

Improve work efficiency and user experience. Traditional hoses need to be manually reeled after use, which is not only time-consuming and labor-intensive, but also prone to kinking or entanglement of the hose due to improper operation, affecting the next use. The reel is equipped with an automatic recovery spring, which allows the hose to be quickly and evenly reeled into the reel, without the need for manual tidying by the user, greatly reducing the labor intensity. With the roller guide mechanism, the hose is pulled out and recovered smoothly, avoiding entanglement and jamming, allowing users to focus on the cleaning task itself, improving overall work efficiency and experience. This function of the reel is particularly important for users who move frequently and work for long periods of time, reducing repetitive work and improving work rhythm.

Improve system cleanliness and work safety. Whether in industrial workshops, car washes or home courtyards, messy stacked hoses not only affect the appearance, but are also very likely to become a hidden danger of tripping accidents. The high-pressure washer hose reel uses a scientific hose storage and guidance design to neatly fix the hose to avoid slipping and entanglement during dragging. Standardized storage management helps users keep the working environment clean and improve space utilization, and also provides safer operating conditions for operators, reducing the probability of accidents. This safety advantage is particularly significant in places with dense crowds or slippery ground.

Supports high-voltage output and stable system operation. High-pressure cleaning equipment has extremely high requirements for the sealing and pressure-bearing capacity of hoses and reels. World-class hose reels use industrial-grade rotary joints with high-pressure sealing functions, which can withstand hundreds or even thousands of bar of working pressure to ensure that the water flow does not leak and the transmission is stable. At the same time, the reel body is made of high-strength materials to ensure structural strength and durability, and avoid deformation or breakage under the impact of high-pressure water flow. Some high-end reels are also designed with explosion-proof pressure relief mechanisms, which can automatically release pressure when the system pressure is abnormal to protect the safety of equipment and operators. These designs enable hose reels to work stably in high-intensity use environments and improve the overall performance of the system.

Save space, easy to install and deploy in multiple scenarios. Hose reels can be installed in various forms, including wall-mounted plates, ground-mounted plates, and vehicle-mounted mobile plates. Wall-mounted plates take up little space, are suitable for fixed workstations, and are easy to use; floor-mounted reels are easy to move flexibly and can adapt to different working environments; vehicle-mounted reels are designed for mobile cleaning, and can be used with high-pressure cleaning vehicles to achieve rapid on-site pipe laying and retrieval. The various installation methods meet the actual needs of different users, making the reel widely used in various scenarios such as industrial, commercial, household and mobile cleaning, greatly improving work efficiency and flexibility.

As an important part of the high-pressure cleaning system, the high-pressure washer hose reel has a wide range of application scenarios. According to different environments and usage requirements, the design and function of the hose reel also have different focuses. The following is based on five typical application scenarios to deeply analyze the specific requirements of each scenario for the high-pressure washer hose reel and its response strategies.

In the field of household high-pressure cleaning, such as garden, vehicle cleaning and daily cleaning of sidewalks, users usually use the equipment less frequently, so the performance requirements of the reel are relatively mild. Household hose reels pay more attention to lightness and economy. The design tends to use lightweight materials to ensure easy carrying and operation. At the same time, the price is affordable to meet the budget needs of home users. The reel has a simple structure, and the automatic retraction function is mostly spring-type, which ensures easy use and reduces maintenance difficulty. Although the working pressure is low, the hose and connectors are still required to have a certain durability and water leakage prevention ability to ensure the cleaning effect and usage experience.

The cleaning tasks of equipment and floors in industrial workshops put forward higher performance standards for hose reels. The industrial environment has high work intensity and high cleaning frequency. The hose must withstand the impact of high-pressure water flow and repeated stretching and winding for a long time. Such reels are usually made of sturdy steel or high-strength alloy materials, with good impact and wear resistance. The reel is equipped with more advanced automatic recovery springs and brakes to ensure that the hose is not easily entangled or damaged during high-frequency use. At the same time, the high corrosion-resistant coating and sealing design can effectively resist the common chemical vapors and oil stains in the workshop and extend the life of the equipment. In order to improve work efficiency, industrial reels may also be equipped with additional devices such as pressure gauges and water filters for easy monitoring and maintenance.

The fields of agricultural irrigation and facility cleaning have strict requirements on the weather resistance and corrosion resistance of hose reels. Greenhouse cultivation, high humidity environment and the use of pesticides and fertilizers may cause corrosive damage to the reel materials. Therefore, agricultural hose reels usually use polymer composite materials and special rubber seals to resist high temperature, high humidity and chemical erosion. The reel structure design also focuses on dust and water resistance to ensure that it remains in good working condition in a changing outdoor environment. The flexible installation method enables it to adapt to the complex layout inside the greenhouse and achieve precise irrigation and facility maintenance. At the same time, the easy-to-operate automatic recovery system reduces the labor intensity of farmers and improves work efficiency.

The commercial car wash industry, especially the application of high-end car wash shops and automated car wash equipment, has more stringent requirements on the performance of hose reels. The car wash process requires high frequency and long-term operation. The hose reel must not only ensure high-pressure stable output, but also have anti-winding, anti-leakage and wear-resistant properties. In order to meet the automated cleaning process, commercial reels are mostly equipped with electric automatic reeling systems. Users only need to press a button to complete the reeling and releasing of the hose, which greatly improves the convenience of operation. The reel shell is usually made of corrosion-resistant aluminum alloy or stainless steel to ensure the long-term stability of the appearance and performance of the equipment. In addition, the hose guide wheel is precisely designed to prevent the hose from folding or tying when reeling at high speed, ensuring the safe operation of the equipment for a long time.

Mobile cleaning platforms such as mobile cleaning vehicles and emergency cleaning vehicles are another important application area for hose reels. Such reels need to have good mobility adaptability and stability. For this reason, mobile hose reels are usually equipped with a sturdy base and wear-resistant rollers to facilitate the free movement of the vehicle in different places. The support frame is reasonably designed to ensure that the reel does not shake or fall off during driving. Due to the changing use environment, the reel material must be both lightweight and strong, which is convenient for transportation and can withstand road bumps and impacts. The quick connector and swivel connector design ensures the reliability of water supply and the flexibility of connection, meeting the dual needs of efficiency and safety for emergency and on-site cleaning.

English

English русский

русский

0086-13003738672

0086-13003738672