ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

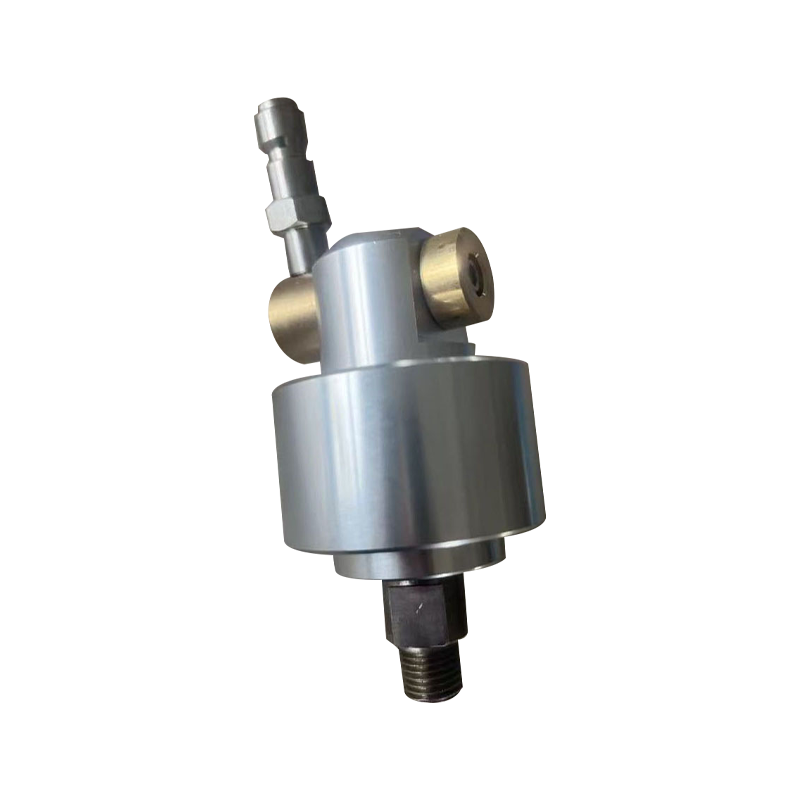

As a famous China Flat Surface Cleaner Manufacturers and Flat Surface Cleaner Suppliers, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

Certificate Of Honor

NEWS

-

How does a Pressure Washer Filter protect the pump and nozzle from debris and particulate contamination during operation?

Primary Barrier Against ContaminantsA Pressure Washer Filter functions as the first line of defense in the water intake system, intercepting particles and contaminants before they can enter critical components. Water sources—whether municipal, well, or pond water—often contain microscopic debris s...

READ MORE -

How does the Ball Quick Coupling perform under repeated connection and disconnection cycles, and what is its rated service life?

1. Durability of Structural Components The Ball Quick Coupling is specifically designed for high-cycle operations, where repeated connection and disconnection are routine. Its structural components, including the housing, balls, locking sleeve, and internal retainers, are typically manufactured from...

READ MORE -

How does the Chromed Steel Spray Gun Barrel interact with various nozzle types and air pressure settings to achieve precise coating applications?

Precision Through Barrel-Nozzle Compatibility The Chromed Steel Spray Gun Barrel is a critical component in achieving high-quality, consistent coatings. Its chromed interior surface is highly polished, providing a smooth, low-friction pathway for liquid coatings such as paints, lacquers, primers, or...

READ MORE

Message Feedback

Industry Knowledge Extension

Flat surface cleaner is an efficient cleaning tool designed for cleaning large flat areas and is widely used in many fields such as home, business and industry. Its working principle relies on high-pressure water flow through a rotating nozzle or brush disc to evenly spray clean water flow to quickly and effectively remove stains and pollutants on the ground. Unlike traditional high-pressure cleaning guns, flat surface cleaners can provide more uniform water flow coverage, avoiding the problems of uneven water flow and splashing, and are particularly suitable for environments that require large-area cleaning.

The design of flat surface cleaners usually includes a rotating nozzle or brush disc located at the bottom of the device. Through high-speed rotation, the nozzle can cover the entire cleaning area and form a uniform water flow, while the rotating brush disc can help remove stubborn stains. This design not only greatly improves cleaning efficiency, but also makes the water flow more concentrated, thereby reducing water waste. When using it, users do not need to repeatedly move the equipment, and the equipment can clean a large area at one time, saving time and energy.

The bottom of the flat surface cleaner is usually equipped with multiple nozzles to ensure that the water flow is sprayed at different angles, further increasing the thoroughness of cleaning. The rotation of these nozzles distributes the water flow in a relatively uniform manner, ensuring that every part can be cleaned, avoiding omissions and repeated cleaning. This makes the flat surface cleaner an ideal choice for efficient cleaning of large areas.

At Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd., we are committed to incorporating the latest technology and design concepts into the production of flat surface cleaners. Through advanced production equipment and a strict quality control system, we ensure that each flat surface cleaner can provide efficient and stable performance to meet the diverse needs of our customers. Our R&D team always adheres to the concept of combining innovation and practicality, and continuously improves the quality and function of our products to adapt them to different cleaning scenarios and needs.

Flat surface cleaners have been widely used in all walks of life due to their efficient and uniform cleaning capabilities. First of all, in home and residential environments, flat surface cleaners are widely used to clean large areas of hard surfaces such as driveways, courtyards, and sidewalks. These places are usually outdoor environments, which are prone to dust, stains or oil stains. Using traditional cleaning tools to clean them is not only time-consuming and labor-intensive, but the results are often unsatisfactory. The design of the flat surface cleaner enables it to complete large-area cleaning tasks in a short time, avoiding the trouble caused by splashing water and repeated cleaning during the cleaning process.

In the commercial field, especially in large public areas such as shopping malls, commercial plazas, and parking lots, the demand for flat surface cleaners is also very high. These areas need to be kept clean and tidy, especially during high-traffic periods, and are often faced with challenges such as dust, oil stains, and garbage. The flat surface cleaner can effectively cope with these challenges and greatly improve cleaning efficiency. Its rotating nozzle and brush disc design can quickly remove stains on the ground, reducing the tedious work of manual cleaning required by traditional cleaning methods.

In the industrial field, flat surface cleaners also play an important role, especially in places such as workshop floors and factory exterior walls that need to clean oil stains, chemical residues or industrial waste stains. Using high-pressure water flow with rotating nozzles and brush discs can quickly remove stubborn pollutants, restore the cleanliness of the ground and walls, ensure the cleanliness of the production environment, and improve work efficiency.

With the improvement of environmental awareness, the market demand for flat surface cleaners is gradually increasing. Its design can not only improve cleaning efficiency, but also effectively reduce water waste, meeting the requirements of water conservation and environmental protection. Therefore, the flat surface cleaner is not only a tool for commercial cleaning, but also an important representative of environmentally friendly equipment. Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd.'s technological innovation in this field enables us to provide more efficient and environmentally friendly flat surface cleaners, helping customers improve cleaning efficiency, reduce water consumption, and meet the sustainable development needs of the modern market.

The long-term stable operation and efficient cleaning effect of the flat surface cleaner depend on its good maintenance and care. Although the flat surface cleaner is designed to be sturdy and adaptable to various harsh working environments, regular maintenance and care cannot be ignored in order to extend its service life and ensure that it always maintains optimal performance.

Cleaning the nozzle and brush plate is the most basic maintenance step. After each use, the user should immediately check and clean the nozzle and brush plate to ensure that there are no impurities, oil or dust blocking the nozzle. If the nozzle is blocked, it will cause uneven water flow, which will affect the cleaning effect. Use clean water to clean the nozzle to ensure that it is unobstructed. At the same time, the brush plate also needs to be checked for wear regularly, especially for equipment that has been used for a long time, the brush plate may be damaged or worn, affecting the cleaning effect. At this time, the brush plate needs to be replaced in time to ensure that the cleaning work goes smoothly.

Inspection of high-pressure hoses and equipment connectors is also crucial. Hoses and connectors are key components of flat surface cleaners. After long-term use, they may age, crack or loosen, which will cause water leakage and even damage the equipment. Therefore, check the sealing of hoses and connectors regularly to ensure that there is no water leakage. For hoses and connectors that have aged or damaged, they should be replaced immediately.

Avoiding long-term continuous operation of the equipment is also an important aspect of maintenance. Although the flat surface cleaner is designed to be sturdy, long-term overload work will accelerate component wear and affect the performance of the equipment. It is recommended to take a proper break while working and avoid long-term continuous high-intensity use. After each work, give the equipment appropriate time to cool down to prevent overheating and damage to internal components.

The storage of the equipment also affects its service life. After use, the equipment should be stored in a dry and cool place to avoid exposure to high temperature or humidity. When not in use for a long time, the water in the water pipe should be drained to prevent the water pipe from freezing or the internal parts from rusting. Proper storage conditions can effectively extend the service life of the equipment.

English

English русский

русский

0086-13003738672

0086-13003738672