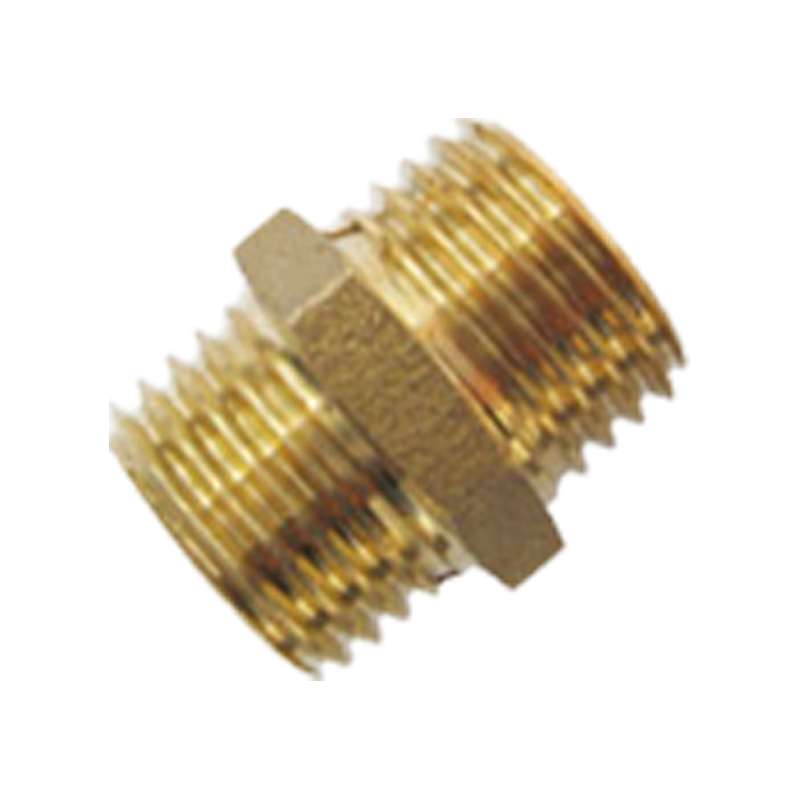

Brass external hexagon threaded joints are commonly used as a transition joint for cleaning pipe con...

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Other Coupling Manufacturers and Other Coupling Suppliers, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

NEWS

-

What lubrication or assembly considerations are necessary to maintain smooth operation of the Ball Quick Coupling?

Importance of Proper Lubrication — Lubrication is a critical factor in ensuring the smooth engagement, disengagement, and overall reliability of a Ball Quick Coupling. The internal mechanism, including the ball lock system, sleeve, seals, and spring components, operates under high stress and frequ...

READ MORE -

What design features of the Weep Trigger Spray Gun prevent clogging or buildup during use with thick or particulate-laden liquids?

Wide-Bore Fluid Channels: The Weep Trigger Spray Gun incorporates fluid channels that are significantly wider than those found in standard spray guns, specifically designed to handle high-viscosity fluids and liquids containing particulate matter. The increased internal diameter reduces resistance...

READ MORE -

How does the Weep Trigger Spray Gun maintain spray consistency when used in high-pressure or high-volume industrial environments?

Precision Internal Valve and Fluid Control Mechanisms: The Weep Trigger Spray Gun utilizes a high-precision internal valve system engineered to regulate fluid flow accurately regardless of variations in input pressure. In high-volume or industrial environments, fluid supply pressure can fluctuate ...

READ MORE

Message Feedback

Industry Knowledge Extension

The diversity of processing technology and selection basis

The common other brass couplings manufacturing processes in the industry currently include the following:

Hot Forging

Cold Forging

CNC Precision Machining

Gravity Casting or Sand Casting

Each process is used in the production process of Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd., and its selection depends on the structural complexity, use environment, sealing accuracy requirements and batch cost control of the product.

The impact of different processes on sealing performance

1. Hot forging process: improve material density and reduce leakage risk

Hot forging is a process that applies pressure to metal billets at high temperatures to form them into a preset structure. Compared with casting, the brass structure of hot forging is denser and the grains are refined, which effectively reduces defects such as microcracks and pores that may cause leakage.

At Baige Machinery, many other brass couplings of key structures - such as high-pressure spray gun quick connectors and rotary nozzle connectors - are formed by hot forging. The sealing surface of the precision forged joint is more stable, and it can withstand higher internal pressure and longer sealing life when it is adapted to O-ring or cone seal.

2. CNC finishing: ensure high-precision coupling interface

The final sealing performance of the other brass couplings depends largely on the flatness, concentricity and thread accuracy of the coupling interface. Baige Machinery uses more than 50 advanced CNC equipment to perform secondary finishing on the coupling surface based on hot forgings or cold forgings. Through CNC turning and milling, the tolerance control of ±0.01mm can be achieved to ensure the tight fit of the joint when used in combination with hoses, quick plugs or nozzles.

In addition, CNC machining can accurately cut internal and external threads, greatly reducing the problem of spiral leakage caused by excessive thread gap.

3. Cold forging: improve surface hardness and is suitable for dynamic sealing structures

Cold forging is a process for plastic forming of brass at room temperature. Some of Baige Machinery's frequently used joints that require wear resistance (such as pressure spray gun connectors) are manufactured by cold forging. This process causes the brass material to be work-hardened during processing, enhancing its surface strength and pressure resistance.

For structures with dynamic seals (such as rotary joints), this enhanced surface hardness can effectively resist the wear of the O-ring and improve the stability and service life of the seal.

4. Casting process: suitable for complex structures, but requires strict inspection

For some other brass couplings with complex structures and difficult to forge, the casting process is still an option. Baige Machinery reduces the pores and slag inclusions in the castings as much as possible by improving the mold design and controlling the casting temperature, but it is still necessary to conduct 100% leakage testing after the finished product to ensure that the sealing meets the standard.

Compared with forged parts, cast other brass couplings are slightly inferior in pressure bearing capacity and sealing, and are more suitable for low-pressure or non-critical parts.

Standardization and quality control ensure sealing reliability

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. strictly implements the ISO 9001:2015 quality management system and ensures the processing consistency of each other brass couplings through standardized operating instructions. In addition, the company is equipped with a professional quality inspection team to implement full process control:

100% dimensional inspection of key sealing structures;

Use high-precision leak detection equipment for air tightness testing;

Each batch of products has a traceable batch number to support subsequent tracking.

Analysis of applicable fluid types and application scenarios

Brass is a copper-zinc alloy with good mechanical strength, corrosion resistance and processing performance, so it is suitable for a variety of liquid and gas media. Other Brass Coupling, professionally designed and manufactured by Baige Machinery, has excellent sealing structure and surface accuracy, and can be safely used in the following types of fluid environments:

1. Water (clean water, hot water, industrial water)

Water is the most common type of fluid for brass couplings, suitable for gardening equipment, cleaning machines, household car washing equipment, high-pressure water guns and other fields. Brass quick connectors, spray gun connectors, and rotary nozzle accessories produced by Baige Machinery are widely used in cleaning systems, can withstand working temperatures up to 150°C, and maintain long-term sealing without leakage.

2. Air and compressed gas

Brass has good sealing compatibility with dry air and compressed gas, is not easy to oxidize, and has no volatile pollution, so it is widely used in low-pressure pneumatic systems and inflatable devices. Some of Baige Machinery's pneumatic connector series products use CNC precision-machined threads and O-ring double sealing structures to ensure no leakage within the pressure range below 0.8MPa.

3. Chemical cleaning fluids (neutral or weakly corrosive liquids)

For foaming agents, disinfectants or cleaning chemical liquids used in household or commercial cleaning equipment, Baige Machinery has developed a variety of composite structure brass connectors, the inner wall of which can be equipped with anti-corrosion coatings or use special plastic nesting parts to improve compatibility with chlorine, alcohol, and ether substances. Typical applications include foam pots, foam spray guns, chemical sprayers, etc.

4. Oil fluids (lubricating oil, diesel, etc.)

Brass connectors perform well in conveying oily fluids such as mineral oil, diesel and lubricants, and are not easy to react with grease or be corroded by oil products. Baige Machinery customizes brass quick connectors for mobile refueling equipment for specific customers, which have a self-sealing structure to prevent leakage and dripping contamination.

5. Low-corrosive gases (such as nitrogen, carbon dioxide)

In some applications involving the food industry, cleaning equipment or spray systems, low-corrosive gases such as CO₂, nitrogen, etc. also need to be controlled through high-sealing connectors. Baige Machinery ensures that its brass connectors maintain stable operation in such gas delivery through structural optimization and material screening.

Professional control of material and structural adaptability

The impact of different fluids on brass connectors is not only in terms of chemical compatibility, but also includes temperature changes, pressure fluctuations and wear and corrosion caused by long-term use. Baige Machinery has taken the following professional measures to address these issues:

Select high-quality environmentally friendly brass (such as CW617N, C37700) that complies with RoHS and REACH standards;

Optimize sealing structure, such as inner cone, plane + gasket composite seal, to adapt to a variety of pressure levels;

Surface nickel plating or anti-oxidation treatment to enhance corrosion resistance in humid environments;

Use oil-resistant, acid-resistant and alkali-resistant NBR, EPDM or FPM sealing rings to improve adaptability to chemical media.

English

English русский

русский

0086-13003738672

0086-13003738672