KARCHER bayonet quick connector is a special pipe quick connection method for KARCHER cleaning machi...

ABOUT US

14YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd. is established in 2011 and is located in Ningbo, Zhejiang Province, China, adjacent to Ningbo Port and Shanghai Port, with convenient transportation.

As a famous China Bayonet Adapter Manufacturers and Bayonet Adapter Suppliers, we specialize in the production of spray guns, gun barrels, connectors, quick couplings, pipe reelers and accessories, nozzles, rotary sprayers, pressure gauges, chemical sprayers, filters, telescopic rods, water brooms, foam spray pots, foam generators, liquid injectors, atomizers, household accessories, high-pressure hoses and assemblies and other cleaning machine accessories.

The company has a factory area of 5000 square meters, more than 50 types of production equipment, and more than 50 employees. We continuously improve the performance and quality of our products, and now have a "Quality Management System Certificate" that meets the requirements of GB/T 19001-2016/ISO 9001:2015.

We have a dedicated team of engineers to improve existing products, research new products to meet more features and requirements, and we are constantly developing new products every year. We also provide customized services. If you have OEM and ODM requirements, please contact us.

In the past few years, our company has gained the trust and support of a large number of customers with strong research and development capabilities, good quality, timely delivery, and excellent service, and our business scale has continued to expand. In the future, we look forward to working together with more partners from around the world to create a mutually beneficial and win-win future.

NEWS

-

What lubrication or assembly considerations are necessary to maintain smooth operation of the Ball Quick Coupling?

Importance of Proper Lubrication — Lubrication is a critical factor in ensuring the smooth engagement, disengagement, and overall reliability of a Ball Quick Coupling. The internal mechanism, including the ball lock system, sleeve, seals, and spring components, operates under high stress and frequ...

READ MORE -

What design features of the Weep Trigger Spray Gun prevent clogging or buildup during use with thick or particulate-laden liquids?

Wide-Bore Fluid Channels: The Weep Trigger Spray Gun incorporates fluid channels that are significantly wider than those found in standard spray guns, specifically designed to handle high-viscosity fluids and liquids containing particulate matter. The increased internal diameter reduces resistance...

READ MORE -

How does the Weep Trigger Spray Gun maintain spray consistency when used in high-pressure or high-volume industrial environments?

Precision Internal Valve and Fluid Control Mechanisms: The Weep Trigger Spray Gun utilizes a high-precision internal valve system engineered to regulate fluid flow accurately regardless of variations in input pressure. In high-volume or industrial environments, fluid supply pressure can fluctuate ...

READ MORE

Message Feedback

Industry Knowledge Extension

The structural principle of Bayonet Adapter

The structural design of the bayonet adapter is inspired by the quick insertion and rotation locking method of the bayonet gun. It is mainly composed of two parts: plug (Male End) and socket (Female End). The typical structure includes the following core components:

Locking lugs (Lugs): located on the side of the plug, used to engage with the guide groove inside the socket.

Guide slots (Bayonet Slots): usually in "L" shape or spiral shape, used to guide the plug to rotate and lock.

Compression spring or sealing ring: used to improve the tightness of the connection and ensure air tightness or liquid tightness.

Limiting device: prevent excessive rotation or misoperation, and improve safety of use.

When connecting, the user only needs to insert the plug into the socket and rotate it clockwise to the card position, and the lug will lock with the guide groove to form a secure connection. Compared with the traditional threaded connection method, the biggest advantage of Bayonet Adapter is fast operation, strong vibration resistance, and high disassembly and assembly efficiency, especially suitable for industrial scenarios where pipelines or accessories need to be frequently replaced.

Practical application in cleaning equipment

In Ningbo Yinzhou Baige Machinery Manufacturing Co., Ltd.'s high-pressure cleaning machine products and spray gun systems, Bayonet Adapter is often used in the following key parts:

Quick connection between spray gun and pipeline

In our self-designed series of spray gun products, the bayonet connection structure is widely used, so that operators can complete equipment assembly or maintenance in seconds, improving work efficiency.

Safe connection between high-pressure hose and nozzle assembly

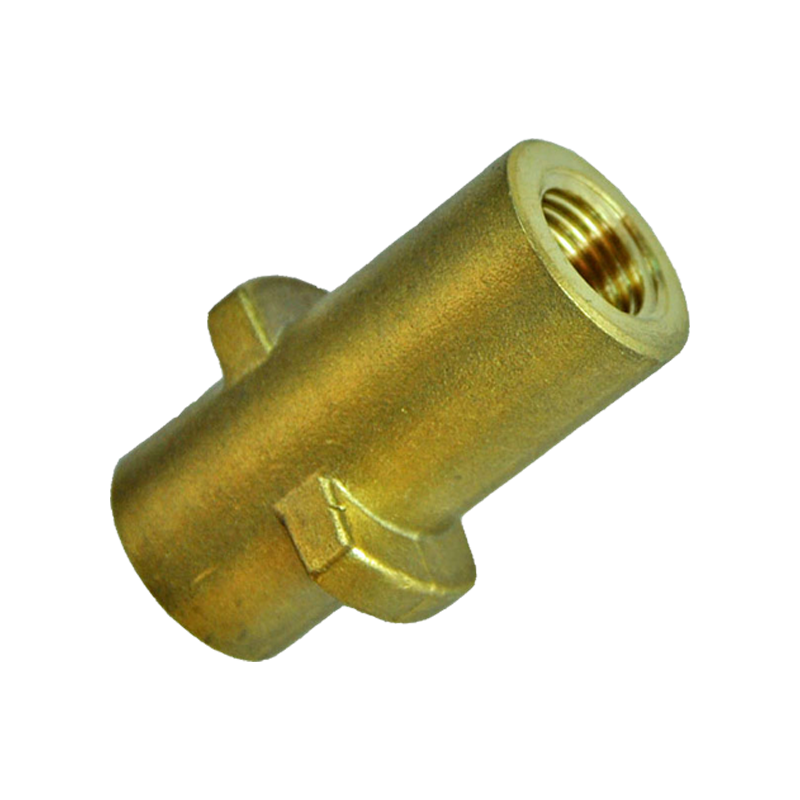

For high-pressure cleaning scenarios, the connection strength is directly related to operational safety. Baige Machinery uses high-strength stainless steel or brass Bayonet Adapter, and adds sealing rings and anti-rotation lock structures at key interfaces to ensure stability and reliability under high-pressure environments.

Foam pot and foam nozzle connection system

Many of our foam spray pots and foam generators are equipped with self-developed bayonet adapters, which enable them to quickly connect to the main cleaning system and are also convenient for cleaning and maintenance after use.

Advantages of Baige Machinery in Bayonet Adapter Manufacturing

As a professional enterprise established in 2011 and located in Ningbo, a major manufacturing city in China, Baige Machinery has over 5,000 square meters of modern factory buildings and over 50 sets of advanced production equipment. We have a complete production chain from raw material procurement → CNC precision machining → surface treatment → strict assembly inspection.

Professional design and customization services

Our engineering team has rich experience in product development and can provide customized suggestions from structure to materials according to the customer's use environment to meet OEM/ODM personalized needs. For bayonet adapter products, we can support customized development of multiple locking forms (two ears, three ears), multiple materials (brass, stainless steel, plastic), and multiple sizes (1/4", 3/8", 1/2", etc.).

Strict quality control system

Baige Machinery has passed ISO 9001:2015 quality management system certification. Each batch of Bayonet Adapter must pass pressure test, sealing test, plug-in life test and corrosion test before leaving the factory to ensure long-term stable operation in actual use.

Industry chain advantages and global services

Relying on the geographical advantages of Ningbo and Shanghai ports, our products can be shipped quickly to the global market. Over the years, Baige Machinery has won the trust and support of domestic and foreign customers with its good quality and service, and its business scope covers Europe, the United States, the Middle East, Southeast Asia and other regions.

Mechanical properties: the first guarantee of connection strength

The bayonet adapter needs to withstand frequent plug-in and pull-out operations, and at the same time withstand the pressure of liquid or gas during work. Therefore, the tensile strength, yield strength and fatigue strength of the material It is the basic indicator for material selection.

For high-pressure environments, such as the gun head connection of a high-pressure cleaner, Baige Machinery usually uses 304 stainless steel or 316 stainless steel, which has high strength, stable structure, and is not easy to deform or break due to long-term use.

For products in medium and low pressure environments and where cost control needs to be considered, the company uses high-strength brass alloys, which not only maintain good mechanical strength, but also have certain processability and corrosion resistance.

In addition, Baige Machinery has multiple processing workshops, and through CNC lathes, precision stamping, heat treatment and other process methods, it ensures that each Bayonet Adapter has excellent performance consistency at the load-bearing point.

Corrosion resistance: the key guarantee for long-term reliability

Aayonet adapters are mostly used in outdoor environments, or in contact with corrosive cleaning agents (such as acidic and alkaline chemical solutions), so the corrosion resistance of the material is directly related to the product life and customer experience.

For accessories that are in contact with water or humid environments for a long time, Baige Machinery recommends the use of 316L stainless steel, which exhibits excellent corrosion resistance in chloride and acidic media.

Brass materials are suitable for conventional cleaning operations and strike a good balance between corrosion resistance and conductivity. The brass materials used by Baige Machinery are all RoHS-compliant, and the surface can be nickel-plated or anodized to improve durability.

We verify the stability of the material through a series of experiments such as salt spray tests (NSS, AASS) and chemical corrosion resistance tests to ensure that the Bayonet Adapter still has good sealing and structural integrity in complex working environments.

Temperature resistance and thermal deformation control

When working in high or low temperature environments, the material must have good thermal stability and low thermal expansion coefficient to prevent connection failure or leakage.

Stainless steel materials remain structurally stable in the range of -40°C to +200°C, making them very suitable for high-temperature steam cleaning systems;

When some plastic Bayonet Adapters (such as POM, PA66) are used in light nozzle systems, thermal stabilizers and antioxidants need to be added to the design to avoid loosening or jamming due to thermal expansion and contraction.

Baige Machinery uses thermoforming simulation technology and material ratio optimization to ensure that each plastic joint can also operate stably within the design temperature range.

Processability and economy: balance between production efficiency and cost

In addition to performance requirements, materials must also take into account processing efficiency and economy. Especially in mass customization production, the machinability of materials will directly affect production capacity and delivery cycle.

For example, the stainless steel and brass materials used by Baige Machinery must meet the CNC high-precision cutting performance, which can realize the free switching between small batch rapid proofing and large batch production.

In low-pressure applications or disposable products, we also use injection molding plastic joints, such as using reinforced nylon (PA6+GF) or POM materials, to reduce overall costs while meeting strength requirements.

The company is equipped with more than 50 CNC processing and injection molding equipment of various types. On the basis of ensuring quality, it effectively realizes the whole process service for customers from OEM proofing to mass production.

English

English русский

русский

0086-13003738672

0086-13003738672